In any organization, it’s crucial to have a strong and effective leadership team that drives the company toward success. Leader’s standard work (LSW) is a powerful tool that can help leaders at all levels of an organization achieve continuous improvement goals.

Leader’s Standard Work (LSW) is a set of documented routines and tasks that leaders follow consistently to ensure that they are effectively managing their teams and driving progress toward key objectives.

By implementing LSW leaders can create a culture of accountability, focus on continuous improvement, and foster a sense of teamwork and collaboration among their employees.

In this article, we will understand Leader’s Standard Work (LSW) in detail, explore its benefits, best practices for implementation, and how it can transform your organization. So get ready to take your leadership skills to the next level.

What is a Leaders Standard Work (LSW)?

Leaders Standard Work is a framework for setting up a routine for leaders to ensure that they are actively engaged in continuous improvement efforts and that they are providing consistent leadership to their teams.

It is nothing but a set of structured activities that leaders should perform regularly to ensure they are focused on the right priorities and executing them effectively. With the aim of creating consistency in leadership behavior and decision-making processes.

By standardizing leadership activities, organizations can ensure that everyone is working towards the same goals and following the same processes. This helps to reduce variability and increase process or workplace efficiency.

The purpose of a Leader’s Standard Work (LSW) is to provide a structured approach to managing their time and activities, ensuring that they are focused on the most important tasks and that they are providing the necessary support to their teams.

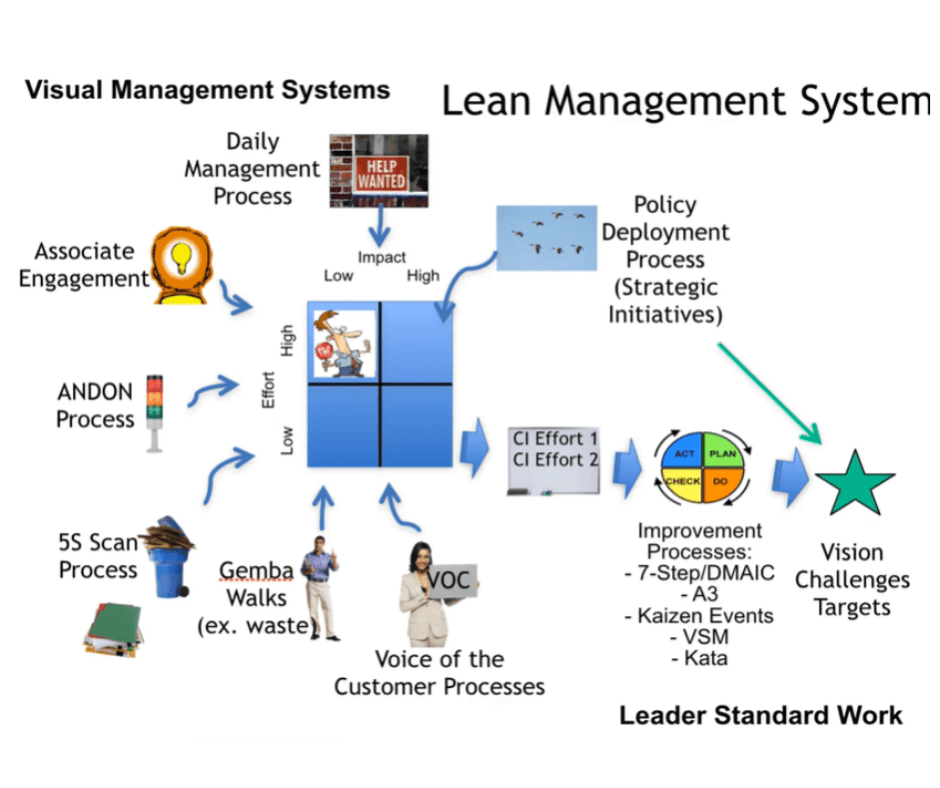

These activities typically include things like reviewing key performance indicators (KPIs), conducting Gemba walks to observe processes, and attending regular team meetings, participating in continuous improvement activities.

By regularly reviewing KPIs and visiting the Gemba, leaders can identify areas for improvement, they can gain a deep understanding of the work being done and the challenges faced by their teams, and take action to address them.

By attending team meetings, they can stay informed about the progress of projects and initiatives and provide guidance as well as support needed. This tool drives continuous improvement and builds a culture of excellence within an organization.

By implementing LSW, leaders can inspire their teams to take ownership of their work and become problem solvers and strive for excellence in everything they do.

For example,

Suppose an XYZ company production manager creates a Leaders Standard Work (LSW) schedule for themselves. They have identified the key tasks that they will complete each day, week, and month to ensure that their team is operating at peak efficiency. The LSW tasks include:

- Gemba walks – Regularly go to the production floor and observe processes and the work environment.

- Daily production meeting – Conduct a daily meeting with the production team to review production targets and quality issues.

- Review of performance metrics – Review daily production, quality, and safety metrics to ensure targets are being out.

- Employee coaching – Spend time coaching and developing team members on their roles and responsibilities.

- Continuous improvement – Participate in continuous improvement initiatives such as kaizen events to improve processes and reduce waste.

- Daily communication – Communicate with other department heads to ensure a smooth flow of work and discuss issues.

- Problem-solving – Work with the team to identify and solve problems as they arise.

I hope that with this example you got the basic idea of a Leader’s Standard Work (LSW). Now let’s further understand the steps to create LSW in detail.

How to standardize the work of Leaders?

You understand the basic concept of a leader’s standard work and how it can help in continuous improvement initiatives. Now let’s understand how to standardize the work of leaders with the help of 5 effective steps –

1. Identify the core responsibilities of a leader

The first step in creating a leader’s standard work is to identify the core responsibilities of the leader. This may include tasks such as setting objectives for the team, reviewing performance, coaching team members, and conducting team meetings.

The goal is to identify the most important tasks and responsibilities that the leader must perform on a daily, weekly, and monthly basis, which are critical to the success of the team and the organization.

For example, let’s say John (a production leader) working with a manufacturing company. The key tasks and responsibilities of the leaders include overseeing the production process,

managing the production team, ensuring on-time delivery of orders as well as the safety of workers, monitoring production quality, and conducting performance evaluations.

2. Break down each responsibility into specific tasks

Once the core responsibility is identified, the next step is to break down each responsibility into specific tasks. This ensures every aspect of the leader’s job is covered and helps to eliminate any ambiguity or confusion.

Determine how often each task needs to be performed and when it should be done. This information should be used to create daily, weekly, and monthly schedules for the later.

For example, Leader may need to monitor production quality every day, conduct performance evaluations once a month and manage production schedules on a weekly basis.

3. Develop a Standardized work procedure for each task.

The next step is to develop a standardized work procedure for each task. This involves documenting the steps that the leader needs to take to complete each task, along with any relevant information or data that they need to collect.

This step ensures that best practices are followed by leaders. For example, for the task of conducting production meetings, the standard work procedure might include the following steps:

- Schedule a daily meeting at the same time and location

- Invite all relevant team members to attend.

- Review the previous day’s production performance.

- Identify any issues or concerns.

- Develop an action plan to address any issues or concerns.

- Follow up on action plan progress in the next meeting.

4. Train the leader and their team members on the SOPs

Once the SOPs are developed, the leader and their team members need to be trained on how to follow them. This ensures that everyone understands how the tasks should be performed & help to create a culture of continuous improvement using the leader’s standard work.

For example, The leaders and their team members would receive training on how to conduct the daily production meetings according to the standardized work procedures.

5. Implement and monitor Leader’s Standard Work

The final step is to implement Leaders Standard Work and monitor its effectiveness. This involves ensuring that the leader is following the SOPs, monitoring the result of their work, and making necessary adjustments to the procedures over time.

This step helps to identify any areas where the procedures may need to be updated or modified to improve efficiency and effectiveness.

For example, the leader could monitor the daily production meetings to ensure that the SOPs are being followed and gather feedback from the team members on how to improve the process.

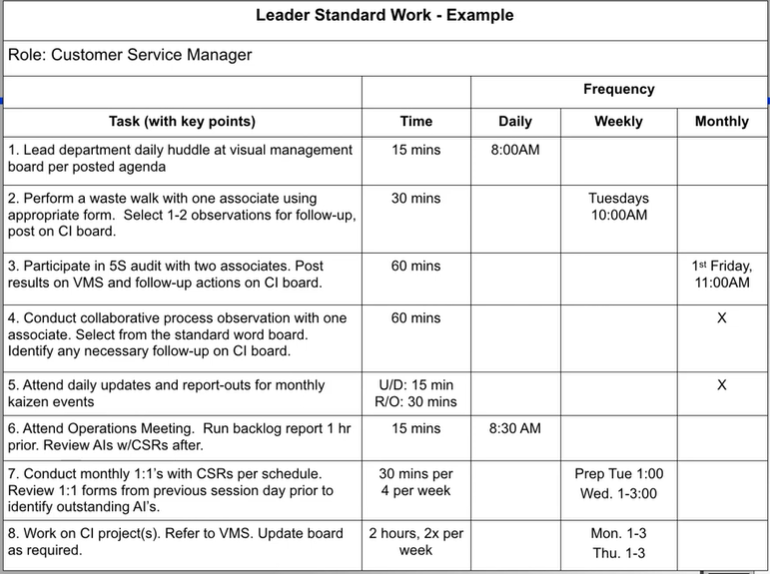

Now let’s see an example of a leader’s standard work document, just read it carefully you will understand this document easily.

This is for your reference so that you can understand how this LSW document looks like. The structure of this document may different for different organizations.

By following these steps under the guidance of an expert, you can create a Leader’s Standard Work that helps to standardize the work of leaders and create a culture of continuous improvement in the organization. (Check out – Leader’s Standard Work template)

Advantages and disadvantages of Leaders Standard Work:

Advantages of LSW:

1. Provides clarity and consistency –

Leader Standard work provides a clear set of expectations for leaders, which helps them to focus on their core responsibilities and carry out their duties consistently. This ensures that everyone in the organization is on the same page and working towards the same goal.

2. Helps identify areas for improvement –

Through regular reviews and updates of LSW, leaders can identify areas for improvement in their processes and practices. This allows them to continuously improve their own work and the work of their team, resulting in a more efficient and effective organization.

3. Supports problem-solving and decision-making –

LSW requires leaders to regularly review key metrics and performance indicators, which helps them to identify potential issues and make informed decisions about how to address them. This promotes a culture of continuous improvement and empowers leaders to take action when necessary.

4. Improved overall company performance –

Leader’s Standard Work can lead to improved performance within the organization. By establishing standard processes and practices, leaders can ensure that work is being performed efficiently and effectively. This can lead to higher productivity, better quality, and improved customer satisfaction.

5. Develop leadership skills –

By consistently carrying out LSW, leaders develop important skills such as time management, delegation, and communication. These skills not only benefit the individual leader but also help to create a culture of leadership development throughout the organization.

Disadvantages of LSW:

1. Sometimes time-consuming –

Implementing Leaders Standard Work requires significant time and effort to develop and maintain standard work procedures, train leaders, and monitor compliance. This can be challenging for organizations that have limited resources or face time constraints.

2. Resistance to change –

Some leaders may resist implementing LSW because it requires time to change their current management practices. This resistance can lead to a lack of buy-in and adoption, which can undermine the effectiveness of the entire system.

3. Sometimes lack of flexibility –

When leaders follow standard work procedures strictly, they may miss out on opportunities to adapt to changing circumstances or take advantage of new ideas. This lack of flexibility can limit creativity and innovation, which are essential for continuous improvement.

4. Over-reliance on documentation –

Leader’s Standard Work focuses heavily on documenting processes and procedures, which can lead to over-reliance on written instructions rather than developing critical thinking skills. This can result in a lack of problem-solving abilities among leaders.

Best Practices for Creating LSW

- LSW should be straightforward and easy to understand. Use clear language and avoid using complicated industry jargon to ensure that everyone on the team can understand the tasks that need to be completed.

- To create engaging LSW, leaders should be involved in the creation process. This allows them to have ownership over their work and ensures that the LSW is tailored to their specific roles and responsibilities.

- Make LSW more visual and engaging by using visual aids like flowcharts, diagrams, and checklists so that team can easily identify the potential areas for improvement.

- Leader’s Standard Work should focus on activities that add value to the customer. This means that you should identify all the tasks that are essential to the process and eliminate those that are not necessary. This will help to streamline your process and reduce waste.

- LSW should encourage collaboration between leaders and their teams. Leaders should be encouraged to seek feedback from their team members and to work together to identify and implement improvements.

- LSW should be reviewed and updated regularly to ensure that it remains relevant and effective. This also provides an opportunity for leaders to reflect on their performance and identify areas for improvement.

Conclusion

By implementing Leader’s Standard Work (LSW), leaders can streamline processes, reduce waste, and increase productivity while improving overall quality. This also improves employee engagement and a culture of continuous improvement.

Leader’s Standard Work requires leaders to be proactive in identifying and solving problems, effectively communicate with their team members, and continuously improve their own skills and knowledge.

So if you are looking to take your organization to the next level, consider implementing Standard Work for Leaders. In this article, I have discussed the concept of LSW in detail with practical examples.

If you found this article useful then please share it in your network and subscribe to get more such articles every week.

Pingback: 14 Principles of Management Every Manager Should Know

Pingback: Leadership Standard Work Template Excel for Auditors - www.shaunstoltz.com