Lean manufacturing is one of the best methods for organizational waste reduction. Waste generation is the biggest problem any organization faces because waste not only disturbs the entire manufacturing or service cycle of the organization but also makes business processes inefficient.

To overcome this problem, in 1930 automotive manufacturer Toyota came up with the concept of the Toyota production system and later it became popular as ‘Lean manufacturing’.

Today, Lean manufacturing is recognized as one of the most popular waste reduction methodologies used all over the world in all types of industries.

In today’s, fast-changing market it becomes important for organizations to implement the concepts of this methodology at the workplace to make processes efficient and fast.

In this, in-depth article I am going to cover every aspect of this powerful methodology like its meaning, brief history, principles, and list of tools used in this methodology along with its advantages and disadvantages.

At the end of this article, you will get a clear picture of why lean manufacturing is useful at your workplace. Let’s start…

What is Lean manufacturing?

Well, you heard about the word ‘Lean’ in many contexts but what does it indicate when we talk about Lean in business or Lean in manufacturing?

When we use it in the context of organization lean means that the organization does not employ more resources than necessary and also does not spend more money than necessary to achieve its final goals.

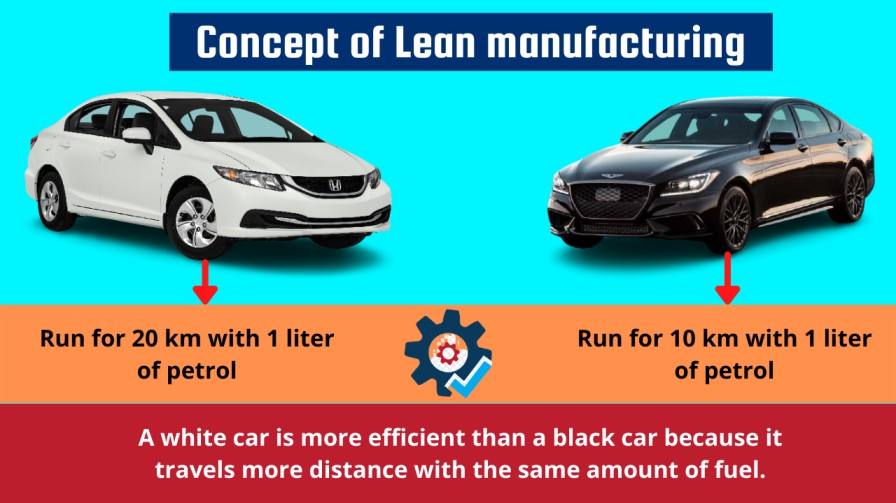

Let’s make it more clear with one example – Suppose there are two same car models with black and white in color. Both are the same model but because of different driving styles, the black car runs for 10 km with 1 liter of petrol and the white car can run 20 km with 1 liter of petrol.

From this, we can conclude that the white car used its resources ( i.e. petrol) in a more economical way as compared to the black car because, with the same amount of petrol, it covers more distance than the black car.

Similarly, in business also many companies produce more products or provide more services with the same number of people in the plant or other resources. Hospitals can treat more patients. Hotels can serve more customers. Car companies manufacture cost-effective cars etc.

So overall, Lean is a methodology to help companies run like a white car, with fewer resources provide the best service i.e creating more value for customers using resources more efficiently and with less budget. This is the essence of the Lean manufacturing methodology.

Lean manufacturing aims to eliminate waste in order to focus on creating the most value possible for customers. It encourages companies to concentrate effort on removing waste while improving the process flow to achieve speed and agility at a lower cost. Its focus is to increase the percentage of value-added work performed by a company.

It is the prescriptive methodology for relatively fast improvements across a variety of processes from administrative to manufacturing applications. It enables your company to identify waste where it exists and also provides the tools to make improvements on the spot.

According to Taiicho Ohno, the chief engineer of Toyota, there are seven types of waste that exist in the organization, and Toyota’s production system or lean manufacturing focuses on eliminating these 7 types of waste. Let’s have a look at that –

- Overproduction – Producing more than the customer requires is waste that causes other waste like inventory cost, manpower, and conveyance to deal with excess product.

- Excess inventory – Inventory at any point is not value-added as it ties up the financial resources of the company and is exposed to the risk of damage, obsolescence, and quality issue. It also needs space and other resources for proper management.

- Defects – Defects and broken equipment result in defective products and subsequently customer dissatisfaction, which needs more resources for solving.

- Waiting – These are waste in time, due to broken machinery, lack of trained staff, shortage of material, inefficient planning, and waiting for material.

- Motion – Unnecessary motion due to poor workflow, poor layout, housekeeping, inconsistent work methods, or lack of standardized procedures, is a waste.

- Overprocessing – This is non-value processing, for which more resources are wasted in production, their wasted movement, and time. Any processing that does not add value to the product is waste.

- Transportation – It includes unnecessary movement of people, tools, inventory, equipment, or products further than needed.

Along with these 7 types of waste, there is one more type of waste added to this list –

- Unused talent – Talent can be wasted when a process doesn’t make the most use of labor or staff available.

Check out – Detail guide on 8 waste in Lean manufacturing with examples and ways to eliminate each.

These 8 types of waste are distributed in 3 main categories see below –

- Muda – The process-related waste and work that is not value-added and the customer is not willing to pay for it.

- Muri – Overburden or waste due to trying to do too much or excessive work.

- Mura – Unevenness or waste because of fluctuating demand. It could be from the customer side i.e. customer requests or due to new products.

History of Lean manufacturing –

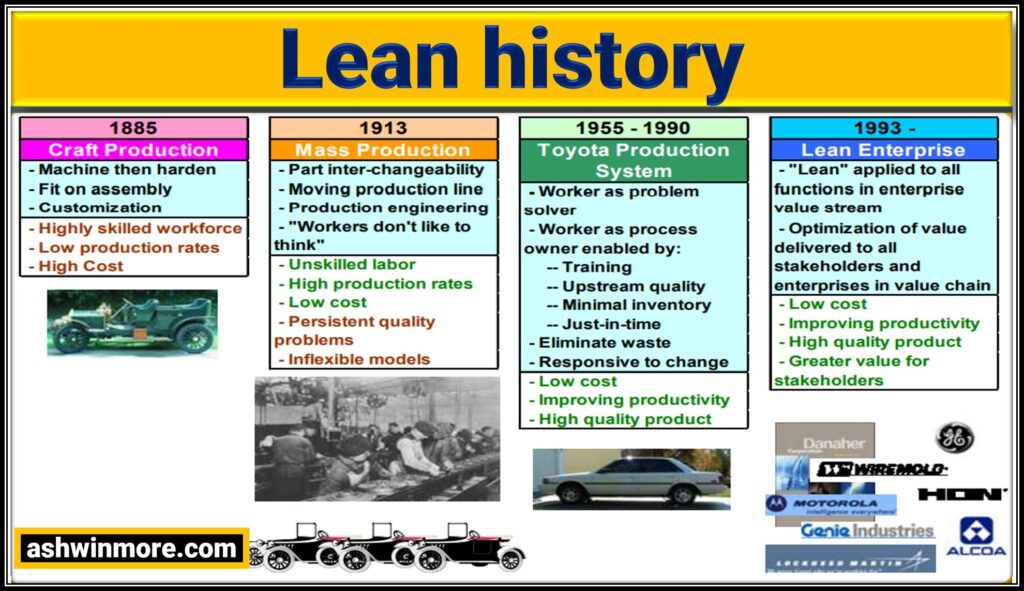

When you first hear about lean manufacturing, I am sure the first thing that comes to your mind is Toyota motors. It all started with Toyota motor corporation. Toyota motors grew out of Toyoda Automatic Loom Works founded in 1926 in japan by the innovator and inventor Sakichi Toyoda.

The firm manufactured state-of-the-art power looms, incorporating Toyoda’s innovative ideas, which drastically improved the weaving productivity at the time. A particular feature of the looms would stop automatically as soon as a thread broke, in other words, a defect would stop the production immediately and automatically.

In 1933 before world war II the company established its automobile department, led by kiichiro Toyoda, the eldest son of sakichi Toyoda. Initially starting in 1935 it began producing trucks for the military and then moved to automobile production.

After the end of world war II with the devastated Japanese economy due to the nuclear attack from America, the company faced difficult business challenges for automobile production like lack of capital, and investment in tooling and equipment was not possible.

During that time Eiji Toyoda was given charge to manage the company. He was searching for a model production system to adopt in order to improve the Toyota automobile production facilities.

He was actually the nephew of Sakichi Toyoda, later he transformed the Toyota Motor Company into the powerhouse of automobile production globally.

In 1940 Toyota Motors was producing cars at a rate of about 200 per year while the Ford motor company in Detroit was making 7000 cars per day.

During a visit in 1950, Eiji Toyoda witnessed the Ford Detroit plant offered a model production system to adopt in order to improve the Toyota automobile production facilities but he also saw several drawbacks in the system.

Later he saw those drawbacks as opportunities for improvement and then he built up a new system that eliminates all possible waste in the production and focuses on value-added activities.

That new system is called the Toyota production system or Lean manufacturing. Because of this system, he became responsible for bringing Toyota motor corporation to profitability and worldwide prominence.

Lean manaufactuirng is the production system created by Toyota to deliver products of right quality, in the right quantity, at the right price to meet the needs of customers.

After that, Taiichi Ohno the Toyota engineer progressed the successful implementation of the Toyota production system with the guidance of Dr.Shiego Shingo who was an industrial engineer and helped to strengthen the TPS system.

TPS focuses on quantity control, quality control, and waste/cost control with continuous improvement. TPS was also known as ‘Just in time manufacturing in the 1980s later it developed into Lean manufacturing in 1990 when the quality engineer John Krafcik highlighted the term ‘Lean’ in his article “The triumph of Lean production system” in 1988.

In that article, John krafcik stated that “Lean manufacturing plants have a higher level of productivity and quality than non-lean plants.” This was further detailed by James Womack and Daniel T Jones in their book ” The Machine that Changed the World” in 1990.

Later on, they defined the 5 principles of Lean implementation in their book ” Lean Thinking: Banish Waste and Create Wealth in your Corporations” in 1996. We will discuss those principles later in this article. So that’s how Lean manufacturing or TPS evolved over time.

5 principles of Lean manufacturing –

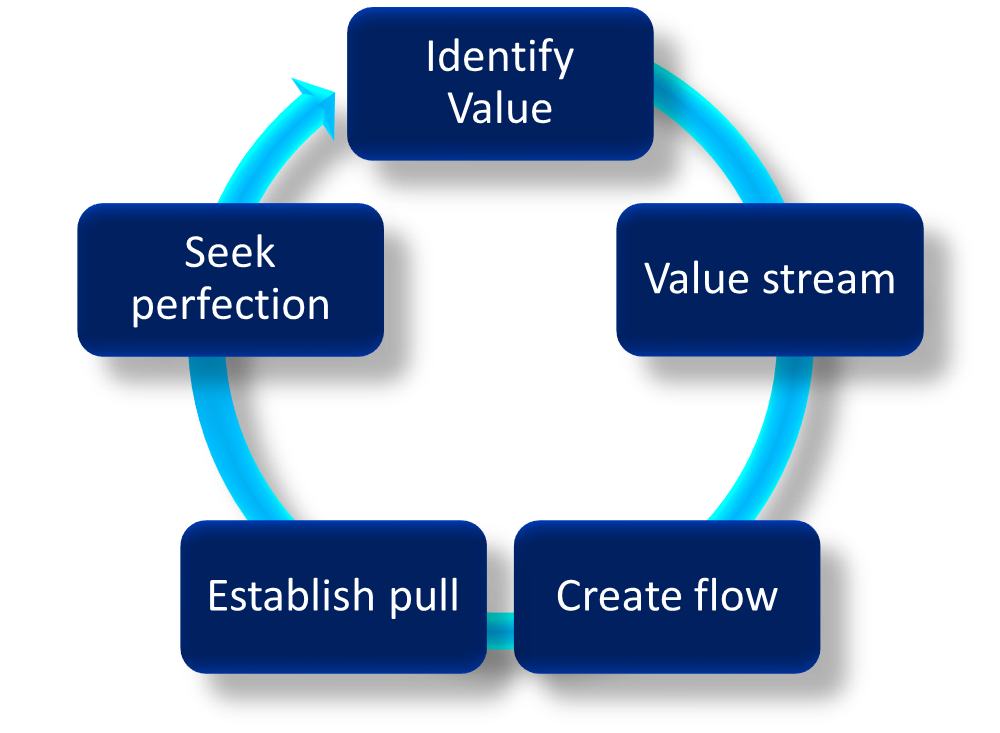

As we discussed James Womack and Daniel T Jones defined the 5 important lean principles in their book “Lean Thinking: Banish Waste and Create Wealth in your corporations.” On these 5 principles, the entire implementation of Lean manufacturing depends so let’s have a look at it…

Identifying value –

- Identifying value should always start with the customer, to who you ship the product or service, or the downstream process customers. If an activity doesn’t add value for a customer then it’s a sign that the process needs to be improved.

- Identifying value is important as it defines the direction of the organization. Value is nothing but understanding customer needs, requirements, or expectations for a specific product or process. Examples of activities that don’t add value include wasted movement, rework, or extra inspection time because you don’t trust the process to get it right the first time.

- Then think about what it is that creates value in the process or product. A good way to do this is to look at it from the customer’s point of view to see what they perceive as value and then try to determine what brings the most value to the organization.

Value stream –

- After identifying the value the next step is mapping the value stream or mapping all the steps and processes that are involved in the product making from 1st step i.e. raw material to the last step i.e. delivering the product to the end customer.

- Value stream mapping requires that you capture lots of data such as cost and quality data. This data gathering includes suppliers and customers as well. Once all the information is processed, you can decide whether any activities or processes need to be restructured in order to improve overall performance.

- This one-page value stream map gives us the flow of products or materials through the process. Also, helps us to identify all the steps in the process that do not add value to the process and then find ways to eliminate such non-value-added process steps.

Create flow –

- Value stream mapping helped to remove all the non-value-added steps from the process, once it is done process becomes full of value-added steps. Then the next principle comes up i.e. to maintain continuous and smooth process flow with no issues, interruptions, delays, and bottlenecks.

- To create a smooth process flow all the departments must come together and perform cross-functional teamwork. It takes a lot of effort during the lean implementation to maintain a smooth process flow.

Establish pull system –

- After achieving a smooth process flow the next step is to establish a pull system in the organization. This is the idea that instead of pushing inventory through planning into the system, allowing the customer to trigger a pull-through of inventory or information to support downstream processes based on consumption.

- By doing that, we can reduce and eliminate wait time that’s associated with traditional process planning, which will lead to minimal inventory being required. Hence this saves a lot of monetary investment.

Seek perfection –

- This step is all about making continuous improvements to a company’s culture. A dedication to continuous improvement is absolutely critical in the practice of Lean. All the organizations would quickly agree that from a safety perspective, the only acceptable goal for safety would be Zero injuries, deaths, lost time, and accidents.

- We need to have the same attitude towards waste and defects in the processes. Well, perfection is an illusion but lean thinking emphasizes that we should be committed to achieving perfection and continuous improvement to drive perfection.

- It is also important that the customer’s voice is heard regarding the elimination of waste and determining what value means. This is the last but most important principle of Lean.

“Lean principles focuses on creating more value for customers with fewer resources.”

Advantages and Disadvantages –

Advantages –

- Eliminate waste – This is the most important advantage or we can say the outcome of Lean culture. Lean principles focus on eliminating all 8 types of waste in the organization and making it completely waste-free by consistently removing non-value-added tasks from the processes.

- Improve customer satisfaction – Lean manufacturing allows delivering products of the right quality, in the right quantity, at the right price to meet the needs of customers which improves customer satisfaction rate.

- Time and cost-saving – By reducing waste of time and resources lean manufacturing not only saves money which is required for resources and time delay on delivery of products or services but also increases the productivity of an organization which makes processes more efficient.

- Competitive advantage – Lean manufacturing techniques introduce the system or culture of continuous improvement in the organization. This culture not only improves the overall performance of the organization but also develops the skills of staff or employees that support changes in the organization.

- When staff absorbs and reacts to changes quickly they become more productive and produce output in less time which makes the organization stand out amongst the competitors. The goal of the organization becomes continuous quality improvement.

Disadvantages –

- Dissatisfaction of employees – Lean is all about continuous improvement in which waste elimination happens continuously. Most of the time, employees or staff are dissatisfied with the continuous changes at the workplace. They are not able to digest these continuous changes at the workplace, it takes a lot of effort to implement the change successfully because this is risky if employees reject the new changes.

- Margin for error is low – Lean emphasizes on pull system of manufacturing or Just in time manufacturing in which manufacturing has been done only when the customer has placed the orders. This system needs a stable flow of material and proper scheduling. But when problems like delays in raw material, maintenance emergencies, interruptions in the production flow, etc. occur that reduce the speed of manufacturing which may result in customer orders delay. Because even a small error in Lean manufacturing can disturb the entire system.

- High cost of implementation – Most of the time when Lean principles are implemented in a company that has never before used it. It is likely that all the production processes and systems will be changed from their current state. This change can bring a high cost of implementation for those companies that are not prepared for the increased expenses of purchasing new equipment/machinery and training programs.

Benefits of Lean in manufacturing –

- It builds up the continuous improvement culture in the organization and focuses on employee skill-building.

- It increases the process flow and speed by removing waste and increasing the percentage of value-added work.

- It makes processes more efficient and productive which results in a high-quality output from the processes.

- With pull system implementation it helps organizations save time and money which is unnecessarily spent on non-value-added tasks.

- Its implementation not only improves customer satisfaction but also improves employee morale.

- It makes the workplace safe and clean by using different Lean tools.

- It helps organizations to provide more value to customers with fewer resources.

List of tools used in Lean manufacturing –

Lean manufacturing has an extensive collection of powerful tools that help the organization in eliminating waste and improving the quality of products or services. Here I am going to list down the 35 most important lean tools that you need to know before implementing this powerful technique.

We will discuss these 35 tools separately in the upcoming articles. All the tools have different applications but in the end, all contribute toward waste elimination. Let’s have a look at the list of tools –

- 5s (workplace management)

- Kano model (Customer needs analysis)

- Gemba walk (The actual place)

- Value stream mapping

- Muda (waste elimination)

- Heijunka (level scheduling)

- Hoshin kanri (Policy deployment)

- Just in time manufacturing

- Jidoka (Autonomation)

- Andon light

- Bottleneck analysis

- Kanban (Pull system)

- Kaizen (Continous improvement)

- key performance indicators (KPI)

- Continuous flow

- Poka-yoke (Mistake proofing)

- Root cause analysis

- Overall equipment analysis (OEE)

- Plan Do Check Act cycle (PDCA)

- Total Productive Maintenance (TPM)

- Visual factory

- Standardized work

- Single Minute Exchange of Die (SMED)

- Takt time

- Six big losses

- Spaghetti diagram

- Flow diagram

- SMART goals

- One-piece flow

- Demand management

- Cellular manufacturing

- 5 why analysis

- Affinity diagram

- Total quality management

- Right first time and Lean audits

If you want to learn all these tools practically under the guidance of a Lean specialist who spent more than 25 years as a Lean expert then I have a recommendation for you.

I would recommend you to join EALSS Academy’s Lean Expert with 38 Lean Tools live training and 3 certification programs to learn the time metrics in Lean manufacturing with practical examples under the guidance of an expert.

Just click on the above link register for the program and join the official group of EALSS Academy. You can watch 1hrs FREE session recording inside to understand the instructor’s teaching style.

After joining the group support team will provide you with complete details about how to enroll in this program and get certified in 3 levels of Lean. ( Check out – All You Need to know about Lean Expert Live training program)

Lean and Six Sigma –

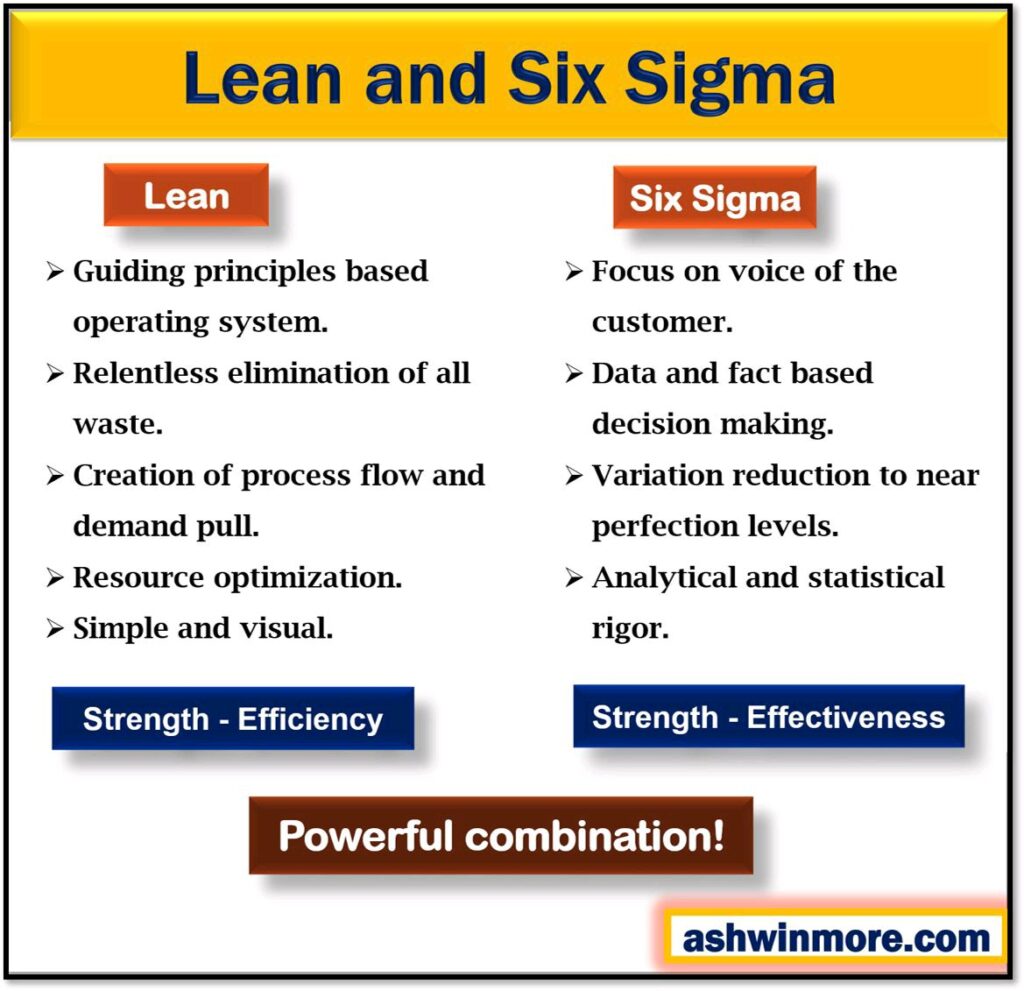

Lean and Six Sigma both methodologies work together, most six sigma approaches incorporate Lean concepts into problem-solving and the control of a process. Now organization uses the term Lean Six Sigma when describing the process improvement method because this needs tools and techniques from both these methodologies.

The organization also believes that the greatest improvement results usually come when we eliminate both defects and waste from the processes.

Lean manufacturing removes all types of waste so that Six Sigma can focus on reducing process variability. Process variation leads to defects, which is the major source of waste.

Defects and waste both cost money and also make the customer unhappy. So Lean and six sigma work together on a common goal i.e. to increase customer satisfaction rate by reducing defects and waste from the processes. That’s how both these methodologies related to each other.

Still, both methodologies have some differences that we need to understand, let’s summarize those differences here, and for a full understanding of how Lean and Six Sigma differ from each other check out the below article.

Check out – Lean Vs Six Sigma: Important differences between two methodologies

Top 10 Lean manufacturing companies in the world –

- Toyota

- Ford

- Intel

- Nike

- John Deere

- Textron

- Parker Hannifin

- Illinois tool works

- Caterpillar Inc.

- Kimberley Clark Corporation

Check out –Details about the top 10 Lean manufacturing companies in the world.

Conclusion –

Lean manufacturing is not only just a process improvement methodology but also a continuous improvement culture that an organization wants to adopt in order to improve the overall performance of the company with few or available resources.

In this article, we understood every aspect of Lean manufacturing like the concept of Lean, its history, and the 5 important principles on which this methodology is based.

Along with that we also discussed the advantages, disadvantages, and benefits. In the end, we saw how Lean and Six Sigma both methods are powerful combinations for process improvement. I hope you got this.

If you found this article useful then please share it in your network and subscribe to get more such articles.

Pingback: What is 5s in Lean? Understand in detail

Pingback: What is the 7 qc tools for process improvement?

Very interesting

Pingback: The Waste of Motion: How to Reduce it? - Everything about Lean Six Sigma

Pingback: What is a Value Stream Mapping? Complete guide for 2023

Pingback: Kaizen Tools: 5 Tools You Must Know for Continuous Improvement

Pingback: 3M Muda Mura Muri : The Toyota 3M Model

Pingback: Standard Work in Lean Manufacturing: How to Apply at Workplace?

Pingback: Explain Total Quality Management and Its 8 Key Principles

Pingback: How Visual Factory can help you Improve Process Efficiency?

Pingback: What is Jidoka Autonomation? Complete Guide For 2024