Have you ever wondered why some companies can deliver products faster than others? Let me tell you the answer lies around understanding the 2 critical time metrics Lead time vs Cycle time differences.

By understanding the Lead time vs Cycle time differences you can uncover hidden inefficiencies, identify areas for improvement, streamline your processes, and ultimately deliver products/services faster and more reliably to your customers.

In this article, I will discuss the Lead time vs Cycle time differences in detail along with their practical examples and key components. In the end, I will also discuss the practical strategies to manage these 2 time metrics.

Are you ready to improve production efficiency by managing the Lead Time and Cycle time? Then Let’s get started…

What is Lead Time?

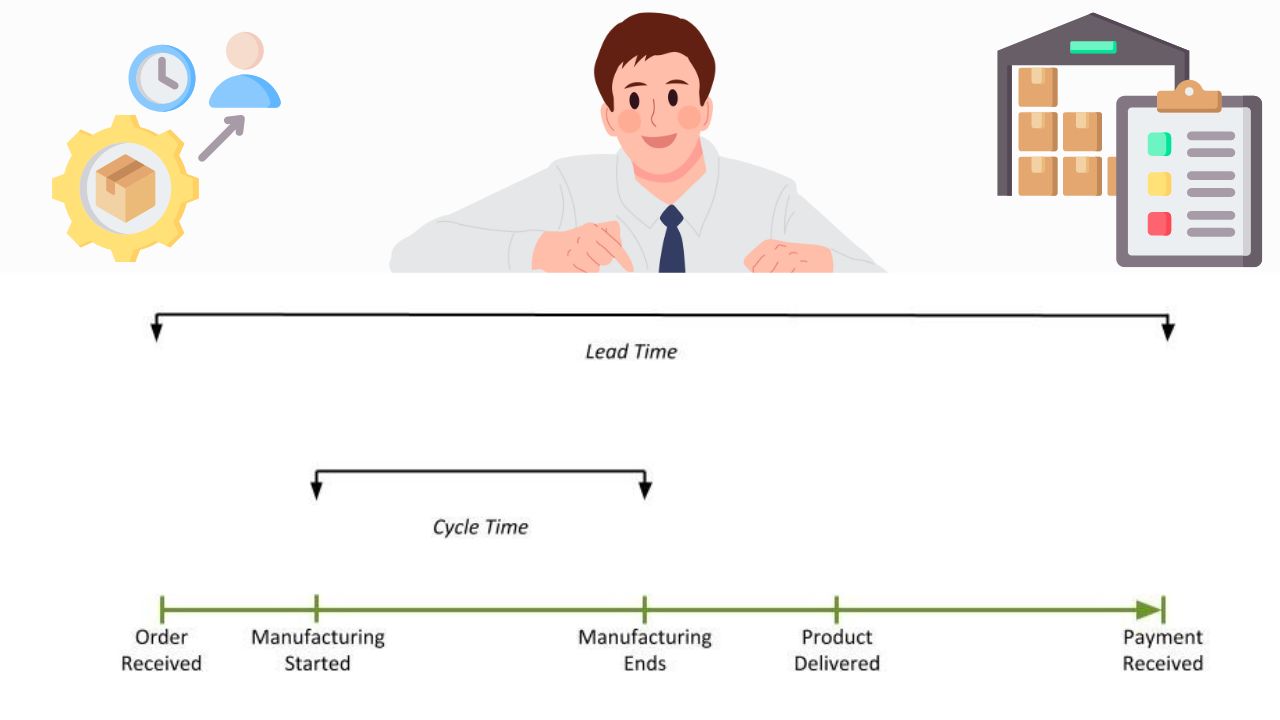

Before comparing Lead time vs Cycle time, let me tell you what lead time is. Lead time in lean refers to the total time it takes from the moment a customer places an order until the final product is delivered.

It’s a comprehensive measure that includes every phase of the process, from the initial request to the moment the product reaches the customer.

Lead time is a critical measure because it reflects how efficiently a company can fulfill customer orders and respond to market demands.

Understanding and optimizing lead time is important for meeting customer expectations, improving operational efficiency, and maintaining competitiveness.

By focusing on reducing lead time, your company can respond more quickly to market changes, reduce inventory levels, and enhance customer satisfaction.

Components included in Lead Time

- Order processing time: The time taken to receive, process, and confirm the customer’s order. It involves activities like order entry, scheduling, and confirmation.

- Production time: The time required to manufacture the product. It includes all production-related activities such as assembling, machining, testing, and quality control.

- Waiting time: The time products spend waiting at various stages in the process. This can occur if there are delays between different production phases or if the product is waiting for additional processing or assembly.

- Inspection and quality assurance time: The time taken to inspect and ensure that the product meets quality standards before it is shipped to the customer. This step is crucial for maintaining product quality and customer satisfaction.

- Shipping and delivery time: The time required to pack, ship, and deliver the product to the customer. It includes activities like packaging, loading, transportation, and final delivery to the customer’s location.

Practical examples of Lead Time

- In a factory producing laptops, lead time begins when a customer places an order online. It includes order confirmation, the time to assemble the laptop, conduct final testing, and ship it to the customer’s address. If the process takes 7 days, then that laptop’s lead time is 7 days.

- When a customer orders a car, lead time includes everything from order processing to the production of the car including all assembly and painting steps, quality inspections,

- And finally shipping time to deliver the car to the dealership or directly to the customer. If this process takes 20 days then the lead time is 20 days.

- For a bakery supplying custom cakes, lead time starts when a customer places an order for a wedding cake. It includes designing, baking, decorating, and delivering that cake to the event location. If this takes 3 days then the lead time here is 3 days.

What is Cycle Time?

Now you know what lead time is but wait before understanding lead time vs cycle time differences, let me tell you the concept of cycle time. It is the total time it takes to produce a single unit of product from the beginning of the production process to the end.

Unlike lead time, which includes the entire process from receiving the order to delivering the product, cycle time focuses solely on the time spent on the production floor.

It’s a critical measure of process efficiency and helps identify how quickly your production line can complete a task or produce a product. Optimizing cycle time is crucial for lean implementation.

By reducing cycle time you can increase throughput, reduce costs, and improve delivery times. This not only enhances overall efficiency but also allows for greater responsiveness to customer demands and market changes.

Components included in Cycle Time

- Processing time: This time includes all the time spent on actual production activities. It includes any value-added work such as machining, assembling, welding, etc. It’s the time during which the product is being actively worked on.

- Setup time: It refers to the period required to prepare equipment or machinery for production. This might involve changing tools, setting parameters, or configuring machines to meet the specific requirements of the job.

- Waiting time: It is the period when the product is idle, either waiting for the next process to start or for resources such as material or labor to become available.

- Movement time: It involves the time taken to transfer materials, components, or the product itself from one stage of the production process to another.

- Inspection time: This includes any time spent checking the product for quality at various stages of the production process.

Practical examples of Cycle Time

- In a smartphone manufacturing company, cycle time might include the time spent assembling the motherboard, installing the software, and attaching the casing. If the entire process takes 50 min per phone, then the cycle time is 50 min.

- In a bakery producing loaves of bread, the cycle time includes mixing the dough, proofing, baking, cooling, slicing, and packaging. If the total time from mixing to packaging one loaf of bread is 2 hrs, then cycle time is 2 hrs.

- In a car manufacturing plant, the cycle time for assembling a car engine includes the time workers spend assembling parts, the setup time for tools, any waiting time for components, and final inspection before the engine moves to the next stage.

Lead Time vs Cycle Time Differences:

Till now I discussed fundamental concepts of Lead time and Cycle time along with their examples. Now let’s understand the Lead time vs Cycle time differences by considering all the important parameters.

| Parameter | Lead Time | Cycle Time |

| Definition | The total time from the moment when an order is placed until the product is delivered to the customer. | The total time taken to complete one unit of production from start to finish within the production process. |

| Scope | Encompasses the entire process, from order placement to delivery, including delays and waiting periods. | Focus solely on the production phase excluding any delays or waiting periods. |

| Includes component | Processing time, waiting time, transport time, and any delays. | Only the actual working time to produce an item, excluding waiting or downtime. |

| Purpose | Measure the overall efficiency of the process, including order fulfillment and customer satisfaction. | Measure the efficiency of the production process itself, focusing on operational performance. |

| Impacts | Affects customer satisfaction and delivery performance. | Affects production efficiency and capacity utilization. |

| Optimization focus | Reducing lead time involves optimizing the entire value stream, including logistics and inventory management. | Reducing cycle time focuses on streamlining the production process, minimizing setup times, and eliminating bottlenecks. |

| Measurement focus | Lead time is more customer-focused, considering the entire process from their perspective. | Cycle time is more internally focused considering only the time spent on production. |

| Influencing factors | Suppliers delays, production scheduling, inventory levels, transportation, and communication. | Machine efficiency, worker skill level, setup time, and process design. |

| Calculation | Lead time = Order processing time + Production time + Waiting time + Inspection time + Shipping time | Cycle time = Total production time / Number of units produced |

| Example | If a customer orders a product on August 1, and it is delivered on August 10th, the lead time is 9 days. | If it takes 4 hours to manufacture one unit, the cycle time is 4 hrs per unit. |

Now you understand the Lead time vs cycle time differences, but you know we discussed the theory part here you will understand its real use in production when you learn this under the guidance of a Lean specialist.

For that I would recommend you to join EALSS Academy’s Lean Expert with 38 Lean Tools live training and 3 certification programs to learn the time metrics in Lean manufacturing with practical examples under the guidance of an expert.

Just click on the above link register for the program and join the official group of EALSS Academy. You can watch 1hrs FREE session recording inside to understand the instructor’s teaching style.

After joining the group support team will provide you with complete details about how to enroll in this program and get certified in 3 levels of Lean. ( Check out – All You Need to know about Lean Expert Live training program)

Why both time metrics is important in Lean Manufacturing?

Initially, I discussed the lead time and cycle time concepts individually and then discussed the Lead time vs cycle time differences. But you know what, both the time metrics are important for evaluating and enhancing operational performance.

Focusing solely on either lead time or cycle time can lead to imbalances that affect overall efficiency negatively. While lead time measures the entire process from order to delivery, cycle time zooms in on the production phase.

Both metrics are vital for lean implementation that’s why a balanced approach is important. By concentrating on both you ensure that all aspects of the production and delivery process are optimized, not just manufacturing itself.

By managing both lead time and cycle time, your organization can respond more effectively to customer demands by properly optimizing production process flow.

Faster production (shorter cycle time) combined with streamlined order-to-delivery processes (shorter lead time) means you can deliver products quicker with fewer delays and adapt more swiftly to changes in demand.

Conclusion

Recognizing the Lead time vs Cycle time differences allows companies to make targeted improvements. Both time metrics impact production efficiency and customer satisfaction, they address the different aspects of the manufacturing process.

By effectively managing and optimizing both metrics companies can achieve more efficient operations, a competitive edge in the market, enhance customer experiences, and drive continuous improvement.

Alright hopefully, I covered all the important Lead Time vs Cycle time differences and concepts in this article. If you found this article useful then please share it in your network and subscribe to get more such articles every week.

If we keep an eye on both metrics, it will be helpfull in our company analysis and get better desicions, with these data on the table.

Yes, it is essential to focus on both time metrics during Lean implementation. Feel free to share the article in your network. Thank you.