For any organization that wants to stay ahead of the competition, achieving excellence in product/process quality is the most important goal. The control plan is crucial in ensuring sustained quality improvements and achieving excellence in quality.

The control plan is a strategic roadmap designed to monitor, control, and improve processes/product quality. It is useful as a preventive measure against defects and a proactive mechanism for process optimization.

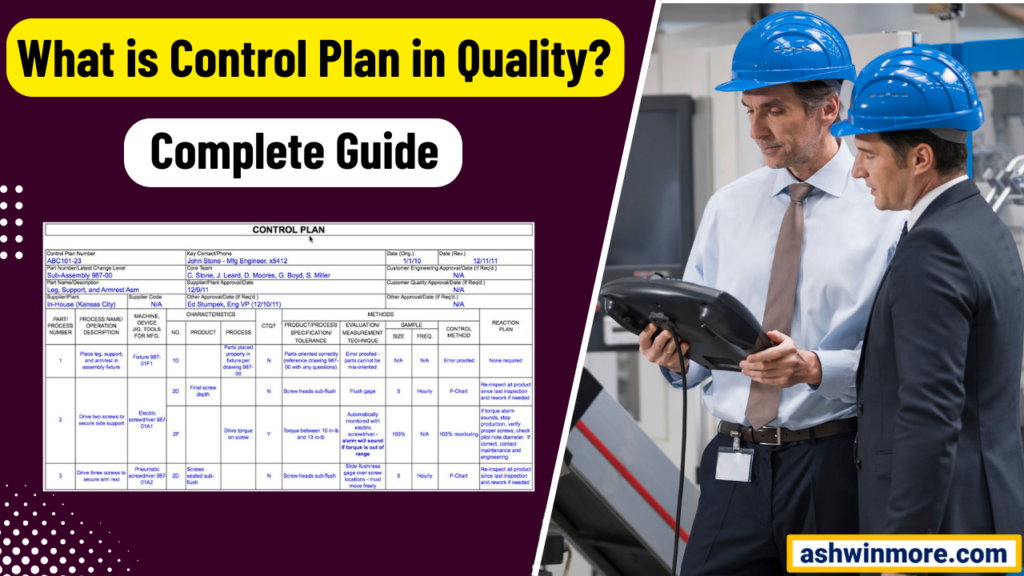

In this article, I will discuss the control plan in quality in detail like the 3 levels of this important document, its importance in quality management, key elements, and common pitfalls to avoid while creating this document.

Are you ready to monitor and control the quality of your processes? Then let’s get started…

What is Control Plan in Quality?

Let’s say you have successfully implemented improvements in a process using Lean Six Sigma tools like DMAIC. You have streamlined the operations, reduced defects, and achieved remarkable efficiency.

Now to ensure your improvement efforts are sustained for the long term and provide you with better results, you need a powerful tool in Quality Management i.e. Control plan.

In simple terms, a control plan in Quality Management is a systematic document that outlines the steps and activities to be taken to maintain and control the quality of a product or process during its development and production.

During Lean Six Sigma process improvement projects also this tool plays an important role in outlining the strategies and tactics to maintain the gains achieved during the improvement phase.

The purpose of control plans is nothing short of visionary. They are the vigilant guardians of quality, foreseeing potential deviations and nipping them in the bud.

By providing a structured roadmap, control plans empower organizations to identify, prevent, and rectify issues before they create quality problems. You can call this a strategic blueprint for excellence.

You know Contol plan is typically developed as part of the Advanced Product Quality Planning (APQP) process which is a framework used in the automotive and other industries for product and process development. However, it is applicable in all types of industries.

If you get into the history of this tool you will understand that the roots of the control plan trace back to early quality management practices, where the emphasis was on inspecting final products to weed out defects.

However, as the industries evolved, so did the need for a more proactive and systematic approach to maintaining the quality of products/processes. The origin of this tool can be linked to the best work of quality gurus like Walter Shewhart and Edward Deming.

Their revolutionary ideas laid the foundation for statistical process control, paving the way for the birth of control plans. Over the years this tool has matured and now not only detects defects or deviations but also prevents them from occuring.

If I talk about the practicality of this living document one thing you should know is that the control plan gets input information from various sources like Process flow diagram, Design failure mode and effect analysis, and Process failure mode effect analysis, etc.

This information is used to create a proper action plan to understand and identify process-related potential issues to ensure that production quality meets customer requirements.

- Process flow diagram: It shows the flow of the process including all steps along with inputs and outputs.

- Process failure mode effect analysis: This identifies the potential failure in the process or products.

- Control plan: This plan follows the PFEMA steps and provides all the details on how the potential issues are checked in process steps and during the inspection of final products.

That means a control plan describes the actions at each phase of a process to conform to pre-determined requirements. This is based on the process flow diagram and PFEMA.

The information input from the process flow diagram and PFEMA frequently changes that’s why the control plan is also continuously updated to provide better results.

There are 2 principles you need to remember while implementing a control plan in quality at your workplace. See below:

- Proactive Quality Management: Control plans empower organizations to anticipate potential variations and risks, creating a shield against defects in the products or variations in the process.

- Foster a culture of accountability and responsibility: Control plans ensure that every individual understands their role in the quality narrative to enhance product/service quality, reduce defects, and elevate customer satisfaction.

The intent of an effective control plan in quality strategy is to:

- Operate processes consistently on target with minimum variation.

- Minimize process tampering (over-adjustment).

- Assure that the process improvements that have been identified and implemented become institutionalized.

- Provide adequate training in all procedures.

- Include the required maintenance schedules.

3 Phases of Control Plan:

Implementing a control plan at different stages of the process helps organizations identify and address quality issues early in the product development process.

This simply helps reduce the likelihood of defects reaching the customers and ensures consistent product quality over time. Let’s see the 3 phases of the control plan implemented at the different stages of the product life cycle.

1. Prototype control plan:

This plan is implemented during the initial stages of product development when prototypes are being created and tested.

It focuses on ensuring that the prototype products meet the specified requirements and that any issues or deviations are identified and addressed early in the process.

This control plan involves monitoring and controlling key characteristics and critical parameters during the prototype phase.

It may include testing methods, inspection procedures, and other quality control measures specific to the prototype stage.

2. Pre-launch control plan:

This plan is implemented as the product is transitioning from the prototype phase to full-scale production but has not yet been officially launched in the market.

It is designed to ensure that the production process is capable of consistently producing products that meet customer requirements before a full-scale launch.

The control plan at this stage involves further refinement of production processes, testing and validation of the manufacturing system, and continuous monitoring of key quality parameters.

It also includes training production personnel and implementing any necessary adjustments based on lessons learned during the prototype phase.

3. Production control plan:

This plan is implemented during the full-scale production of the product after it has been officially launched in the market. It aims to maintain and continuously improve the quality of products throughout the production lifecycle and meet customer expectations consistently.

This control plan involves ongoing monitoring and control of critical quality characteristics, routine inspections, and audits of production processes.

It also includes a feedback loop for continuous improvement to address emerging issues and optimize entire processes for efficiency and quality.

Control Plan elements

The control plan in quality generally follows the standardized format but its details may vary depending on the specific industry or company requirements. Let’s see some of the important components of the control plan:

- Control plan phases: Prototype, Pre-launch, or Production control plan.

- Part/process step number: This is the part or step process number that matches both the process flow diagram and PFMEA.

- Parts/process name: The name or description of the part or process being controlled.

- Control plan number: A unique identifier for the control plan document.

- Revision Number and Date: Indicates the version of the control plan and the date of the latest revision.

- Responsible individuals/teams: Name of the individuals responsible for implementing and maintaining the control plan.

- Approval signature: Signatures of individuals responsible for approving the control plan.

- In-scope processes: Clearly define the processes or steps covered by the control plan.

- Out-of-scope processes: Specify any processes or steps that are not covered by the control plan.

- Key process variables: Identify the critical factors or variables that can affect the quality of the product or service. These are referred to as key process characteristics, or key product characteristics, including dimensions, materials, etc.

- Key characteristics: Specify the critical features or attributes (CTQs) of the product that need to be controlled to ensure quality. Includes dimensions, surface finish, hardness, and other relevant properties.

- Tolerance/specifications limits: Define the acceptable range or limits for each key characteristic. This helps in setting clear boundaries for what is considered acceptable in terms of quality.

- Measurement Control methods: Specify the methods and tools used for measuring and monitoring each key characteristic like Statistcial Process Control, Visual Inspection, and Poka-Yoke.

- Sampling plan: Specify the sampling method and frequency for inspecting and testing the product or process. This ensures that representative samples are taken to assess the quality of output.

- Data collection: Details on how data will be collected, recorded, and analyzed. You can use tools like checksheet or MSA for this.

- Defect classification: Categorize defects based on severity or impact using powerful tools like FMEA and PFMEA.

- Supplier information.

- Response plan: Outline the actions to be taken if a key characteristic deviates from the specified limits. This may include immediate corrective actions and long-term preventive measures.

- Control limits and targets: Define the acceptable range for each characteristic and specify the desired or optimal values for each characteristic. Use control charts and other statistical tools.

- Frequency of monitoring: Define how often the measurements and inspections will be conducted. And also define how and to whom data and reports will be communicated.

- Verification and validation: Details on how the control plan will be verified for effectiveness and specify the criteria for validating the control plan.

- Change management: Describe how changes to the control plan will be managed and documented. Specify the process for obtaining approval for any changes.

- Documentation and records: Specify the documents and records that need to be maintained. Outline the duration and location of record storage.

- Review and audits: Indicate how often the control plan will be reviewed and audited for effectiveness. Define the criteria for evaluating the success of the control plan.

Why develop a Control Plan in Quality Management?

Before understanding how to develop a control plan, you must know why to develop this and how it helps your organization maintain product or process quality. Let’s see some important reasons:

- A control plan helps establish standardized processes and procedures to ensure consistency in the production or service delivery, this reduces the variability and achieves a higher level of quality in the outputs.

- It acts as a preventive measure to identify and address potential sources of errors before they lead to defects or deviations. This reduces the likelihood of defects and rework.

- Control plans in quality monitors and control key process parameters. This allows organizations to identify areas for improvement, optimize processes, and enhance overall efficiency.

- By ensuring that products or services consistently meet or exceed customer expectations, control plans contribute to customer satisfaction which positively impacts the company’s reputation in the market.

- It includes risk assessment and mitigation strategies. By identifying potential risks in advance, organizations develop contingency plans to minimize the impact of unforeseen events on product or service quality.

- A control plan helps control and reduce variation in the process, which is essential for achieving top-quality outputs. Control variation is the goal of Lean Six Sigma projects that’s why control plans are also used in the DMAIC framework.

- The control plan collects and analyzes the data at various stages of the production or service delivery process. This data-driven approach enables organizations to make informed decisions, identify trends, and take corrective actions.

- Through regular monitoring, analysis, and adjustment of processes, organizations can identify opportunities for improvement and implement changes to enhance overall quality using control plans.

Common pitfalls to avoid

There are some common pitfalls that you should avoid while developing a control pan in quality. Let’s see them one by one:

1. Lack of Employee engagement:

If employees are not involved or informed about the control measures, they may not fully understand their roles or the importance of following the plan.

Lack of engagement can lead to noncompliance and resistance, ultimately undermining the effectiveness of the control plan in quality.

Solution: Ensure that employees at all levels are engaged in the control plan development process. Ecoaugre feedback, provide training, and communicate the importance of their role in maintaining control.

2. Insufficient data analysis:

An effective control plan in quality relies on accurate and relevant data for decision-making. Insufficient data analysis can lead to incorrect decisions making it challenging to identify and address issues within a process.

Without thorough analysis, the organization may miss critical insights which leads to ineffective control measures and an inability to identify the root causes of issues.

Solution: Thoroughly analyze the relevant data before implementing control measures. Use statistical tools and methods to ensure the accuracy and reliability of the data. Regularly review and update data analysis procedures.

3. Overlooking changes in the business environment:

The business environment is dynamic and changes can impact the processes and their associated risks. Overlooking changes such as new regulations, technological advancements or shifts in customer preferences can render existing control plans ineffective.

Solution: Regularly monitor the business environment for any changes that could impact processes. Conduct periodic reviews of the control plan and update it as necessary to reflect changes in the internal or external environment factors.

4. Failure to update control plans regularly:

The control plan should not be a static document. Failure to update them regularly can result in outdated procedures that no longer address the current challenges or risks.

As processes evolve or new information becomes available control plans must be revised to reflect these changes. If not updated regularly they become outdated.

Solution: Establish a schedule for reviewing and updating control plans at regular intervals. Conduct audits, and gather feedback from stakeholders. This ensures plans remain relevant and aligned with the current state of the process.

If you are looking for practical training to learn Lean Six Sigma and get certified in Lean Six Sigma then I would like to recommend you best practical live training program check out – Lean Six Sigma with Minitab live training program and certification.

Conclusion

The control plan emerges as a strategic asset for any organization in today’s competitive marketplace, which offers a systematic and data-driven approach to quality management.

The essence of this tool lies in its ability to identify and mitigate potential deviation from the Standards. The control plan in quality is nothing but a proactive manifesto that empowers organizations to not only meet but exceed customer expectations consistently.

By integrating this tool into the fabric of daily operations, organizations forge a path toward a culture of continuous quality improvement, where the pursuit of excellence becomes an ingrained mindset of every individual working in the organization.

If you found this article useful then please share it in your network and subscribe to get more such articles every week.