Have you ever wondered how amazing products like the Apple phone, Tesla car, and HP laptop, make their way from concept to reality with impeccable quality? That’s where the importance of the 5 phases of APQP (Advanced Product Quality Planning) comes into play.

APQP is a structured approach that helps companies proactively design, develop, and launch products that consistently meet customer requirements.

The 5 phases of APQP act as a compass that guides organizations toward achieving excellence, reducing defects, and delighting customers.

In this article, I will discuss Advanced Product Quality Planning in detail along with its benefits and 5 important phases of APQP, and explore how this systematic approach contributes to the development & launch of high-quality products.

Whether you are an engineer, lean Six Sigma practitioner, quality manager, or entrepreneur who is curious about the secrets behind creating world-class products that exceed customer requirements then this article is for you. Let’s get started…

What is Advanced Product Quality Planning (APQP)?

Imagine you are a business owner and your company manufactures mobile phones, right now you have a new idea for an amazing new phone that has some extra cool features. You are excited about that new phone.

At the same time, you want to make sure that your company’s new phone must be perfect before it reaches the market or in the hands of customers. This is where you need APQP i.e. Advanced Product Quality Planning.

APQP is the best-structured approach to designing new products or processes that satisfy customers. In simple words, it is the planning for product quality in advance to ensure customer satisfaction.

Basically, APQP takes care of understanding the Voice of customers clearly and translating them into requirements, technical specifications, and characteristics. Then it uses these insights to design error-free processes/products to satisfy customer requirements.

It makes the organization think proactively about identifying quality-related problems before they become big and difficult to fix. It helps organizations manage the quality of their products from start to finish of the production process.

Implementation of this tool not only makes customers happy with a high-quality product but also saves money for organizations by fixing quality issues early on and preventing costly rework/repairs.

This powerful tool is actually a part of 5 core tools in the Quality Management System published by Automotive Industries Action Group (AIAG) (5 core tools like FMEA, MSA, SPC, PPAP, and APQP.)

Don’t worry I am not going through all these 5 core tools here, for this article, our focus is on the 5 phases of APQP so other core tools I will discuss in upcoming articles.

In a nutshell, the 5 phases of APQP help organizations streamline their product development process and make it more efficient by reducing waste. It provides a complete step-by-step framework to make sure that you don’t waste resources on unnecessary things.

When to use the 5 phases of APQP?

APQP is useful in developing new quality products. It basically helps you identify all the requirements and expectations in advance, from your stakeholders and external customers.

Because when you know the expectations of stakeholders and customers early on, you get better insights/data and easily avoid misunderstanding.

By doing this, you align the expectations of stakeholders and customers and set the best foundation for a quality product launch.

You know that the DMAIC methodology improves the existing process’s quality similarly, the APQP is useful in modifying the existing products.

It helps you identify what are the modifications required in the product and then assess the impact of those modifications on the product’s quality and performance.

By going through the 5 phases of APQP, you can highlight any potential risks and ensure whatever modifications or changes you are going to do to the product should meet the customer expectations and reduce any negative impact on the product quality.

APQP is also useful in managing complex types of projects where many interdependent tasks and stakholders involves. It basically helps you break down the complex project into small manageable phases with clear milestones.

By doing this, you can easily track the project tasks, mitigate risks and ensure the smooth flow of the project. In a nutshell, if you want a high-quality product that meets customer expectations then you must use APQP.

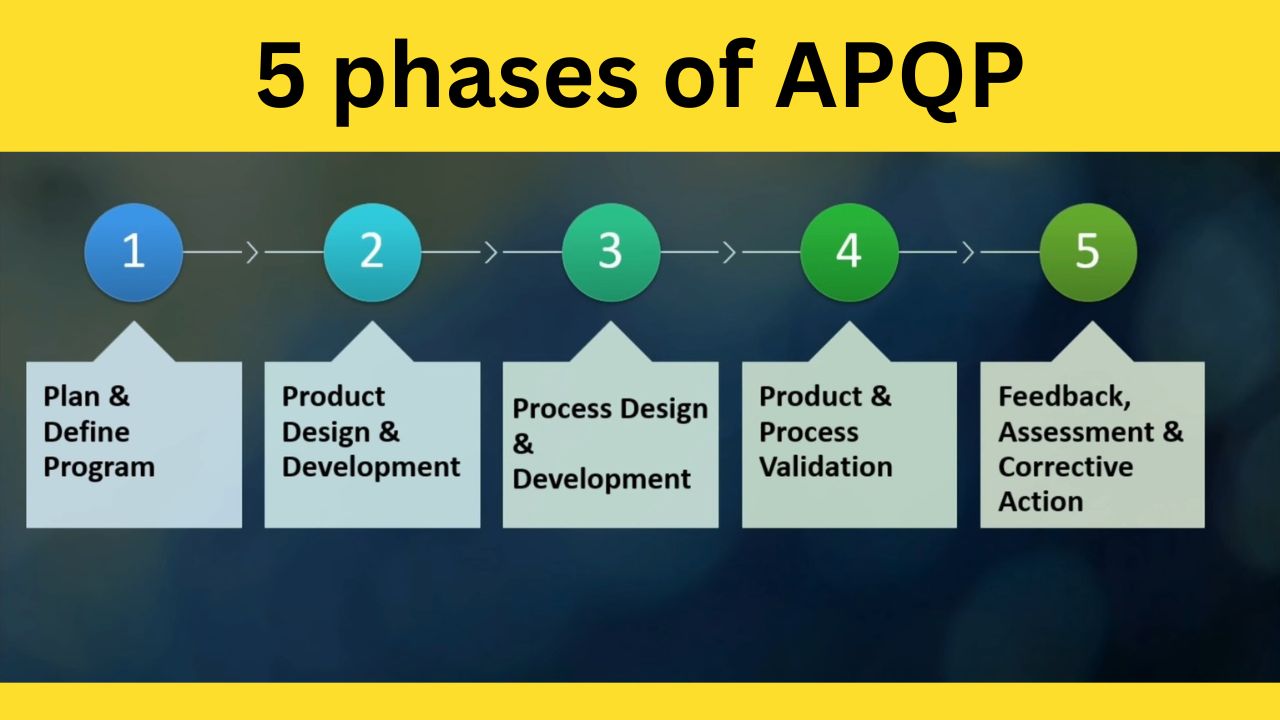

5 phases of APQP:

Now you understand the fundamental concept of APQP and why it is important as well as when to use it. It’s time to get into the depth of all 5 phases of APQP one by one so that it becomes easy for you to implement this at your workplace.

1. Plan and define the program:

The 1st phase of APQP is one of the most important phases out of the 5 phases of APQP because this phase sets the foundation for the APQP implementation.

This phase establishes a cross-functional team together that will be responsible for the planning and execution of the product development project.

This cross-functional team includes people from different departments like representatives from engineering, manufacturing, quality, purchasing, and other relevant departments. This cross-functional team defines the project scope, objectives, and deliverables.

This team set a solid foundation for APQP by identifying customer requirements, determining product/process specifications, and setting quality goals with the proper timeline for the product development project.

Key activities in this phase:

- Understand customer needs and expectations including any specific technical and quality requirements

- Set measurable goals for the product design and the process like quality standards, cost required, and performance targets.

- Develop a detailed schedule that outlines the key milestones and activities for the product development project.

Now let’s see the inputs and outputs of this phase:

Inputs:

- Voice of the customer (market research, Historical warranty, quality information, etc/)

- Business plan/Marketing strategy

- Product/Process benchmark data

- Product/Process assumptions

- Product quality, reliability, life, durability, maintainability, timing, and cost.

- Customer inputs – Identification, traceability, special characteristics, packaging, etc.

Outputs: (these are inputs to phase 2 of APQP)

- Design goals

- Reliability and quality goals

- Preliminary Bill of material

- Preliminary Process Flowchart

- Preliminary Listing of special product and process characteristics

- Product assurance plan

- Management Support (including program timing and planning for resources)

2. Product design and development:

In this phase, the cross-functional team comes into action in which they focus on the design and development of a product or service. The most important thing team does in this phase is convert customer requirements into measurable requirements.

The team translates the customer requirements into specific design characteristics and creates a complete design plan. Here they consider important factors like product functionality, performance, safety, reliability, and manufacturability during the design process.

To validate the product design, the cross-functional team also conducts feasibility studies, prototype development, design reviews, different types of testing, etc.

Key activities in this phase:

- Generate and evaluate various design concepts to meet customer requirements and product development project goals.

- Test and verify the product design through simulations, prototypes, and different types of testing to ensure it meets the set requirements.

- Conduct regular design reviews to evaluate progress, address any potential issues, and ensure the product design aligns with the project goals.

Now let’s see the inputs and outputs of this phase:

Inputs:

Inputs for this phase are the outputs of 1st phase of APQP so please refer to that above.

Outputs:

- Design FMEA/DFMEA

- Design for Manufacturability and Assembly (DMA)

- Design Verification & reviews

- Prototype building

- Prototype control plan

- Engineering Drawings

- Engineering/material specification

- Drawing and specification changes

- Targets for productivity and process capability as well as cost

- Special product and process characteristics

- Gages/testing equipment requirements

- New equipment, tooling, and facilities requirements

- Team feasibility commitment and management support

3. Process design and development:

In this phase, the team shifts its focus to the development of the manufacturing or service delivery process. Here, the team analyzes the product design and determines the optimal production methods, equipment, and tooling required.

The cross-functional team works on creating a detailed plan that enables the efficient production of the product while meeting quality standards. The team also identifies the key process parameters, develops work instructions, and establishes control plans to monitor and control the process.

Key activities in this phase:

- Create a detailed flowchart that outlines the sequence of steps in the manufacturing or service delivery process.

- Develop detailed instructions for the operators and workers to ensure consistent and error-free execution of the process.

- Perform process failure mode and effect analysis to identify and address potential failure modes and risks in the process.

- Establish a control plan that shows the critical control points, and process monitoring methods.

Now let’s see the inputs and outputs of this phase:

Inputs:

Inputs for this phase are the outputs of 2nd phase of APQP so please refer to that above.

Outputs:

- Packaging standards and specifications

- Product/process quality system review

- Process flow chart

- Floor plan layout

- Characteristics Matrix

- Process failure mode and effect analysis

- Pre-launch control plan including poka-yoke devices

- Process instructions

- Measurement system analysis plan

- Preliminary Process Capability Study Plan

- Management support including operator’s staffing and training

4. Product and Process validation:

This phase is all about validating both the process and the product. In product validation, the team focuses on testing the product against customer requirements, conducting performance tests, and ensuring regulatory compliance.

In process validation, the team focuses on running production trials, measuring process capability, and verifying that the process is capable of consistently producing high-quality products.

Key activities in this phase:

- Conduct different types of tests to evaluate the performance, durability, and functionality of the product.

- Assess the process capability to ensure it is capable of meeting the required specifications consistently.

- Perform measurement system analysis to evaluate the measurement tools and techniques used to ensure accurate and reliable product measurements.

Now let’s see the inputs and outputs of this phase:

Inputs:

Inputs for this phase are the outputs of 3rd phase of APQP so please refer to that above.

Outputs:

- Significant production plan

- Measurement system evaluation

- Preliminary process capability study

- Production part approval process (PPAP)

- Production validation testing

- Packaging evaluation

- Production control plan

- Quality planning sign-off

- Management support

5. Feedback assessment and correction action:

This is again one of the important phases out of the 5 phases of APQP because the implementation of this phase will decide the success of the overall implementation of APQP. Here the cross-functional team focuses on monitoring and improving the product & process performance.

The team collects and analyzes important data related to products and processes from various sources like customer feedback, warranty claims, and production metrics. This information is then used to evaluate the effectiveness of the product and process.

Also used to identify areas of improvement in the product or process. After that corrective actions are taken to address any identified issues during this phase, and lessons learned are documented to inform future projects.

Key activities in this phase:

- Continuously monitor product performance, customer satisfaction, and process capability to identify any deviations or opportunities for improvement.

- Implement appropriate actions to address any identified potential issues or non-conformances, including root cause analysis, problem-solving, and process improvements.

- In the end, document the lessons learned throughout the 5 phases of the APQP of the process to improve future product development projects.

Now let’s see the inputs and outputs of this phase:

Inputs:

Inputs for this phase are the outputs of a 4th phase of APQP so please refer to that above.

Feedback and assessment is an ongoing process because you will get constant feedback from any of the phases of APQP i.e. 1st, 2nd, 3rd, and 4th phases. (Check out – AIAG APQP checklist template)

Below are the examples of feedback you may get from the above 4 phases that you need asses and if you find any opportunity to improve then take corrective actions accordingly.

- Design verification & Design reviews

- Drawing & specification changes

- Product process quality system review

- Measurement system evaluation

- Production validation testing

- Feedback from customer

Outputs: (This is an overall output of APQP)

- Reduced variation

- Improved customer satisfaction

- Improved delivery and service

- Effective use of lessons learned/best practices

Benefits of APQP:

APQP prevents problems before they happen by enabling you to identify and address potential issues in advance in the product development process. By preventing problems early on, APQP actually saves your time, money, and resources.

APQP ensures customer satisfaction. Because this method puts the customer at the heart of the product development process. By properly understanding their requirements and expectations, you can design an error-free quality product to fulfill customers’ expectations.

From the 5 phases of APQP, you understood that APQP is a team-based problem-solving method. APQP promotes teamwork, innovation, and creativity, where the team of experts works together on a common goal like creating high-quality products.

It brings people from different departments and backgrounds together, with the help of effective collaboration and communication amongst them APQP helps produce high-quality products.

You know that APQP means Advanced Product Quality Planning, this method actually empowers you to plan your product development process in advance so that everything in the development process happens in a timely manner.

APQP is a proactive approach, it helps you in identifying and assessing the risks involved in the product development process and develop effective strategies to deal with them. By doing this, you can reduce the likelihood of quality issues and production delays.

APQP helps you streamline your processes and ensures efficiency. The 5 phases of APQP help you identify bottlenecks, eliminate waste, and ensure that the entire product development process runs smoothly from start to finish.

APQP emphasizes the philosophy of continuous improvement. It encourages you to regularly review the product development process, analyze the product performance data, and use the lessons learned for the future.

Conclusion

The best thing about the 5 phases of APQP is its applicability across various industries and organizational settings. It is not a one-time effort rather it is an ongoing process that focuses on data-based decision-making and commitment to excellence.

Implementing the 5 phases of APQP organizations promotes collaboration and a culture of continuous improvement, and minimizes errors by identifying issues prior which leads to reduced costs and improved product quality.

Throughout the article, we discussed the 5 phases of APQP in detail including key activities in each phase as well as important deliverables, we also discussed the benefits of implementation of Advanced Product Quality Planning and when to apply this powerful technique.

If you found this article useful then please share it in your network and subscribe to get more such articles every week.

Pingback: Core Tools Of Quality: A Comprehensive Guide of 5 Powerful Tools