Imagine a manufacturing shop floor where waste is minimized, efficiency is very high and every movement happening is value added to the process. That’s what happens when you effectively reduce the 3M Muda, Mura, and Muri from your workplace.

3M Muda, Mura, and Muri are the 3 important categories of waste found in any organization. When you understand how these three categories of waste impact your organization, it becomes easy for you to implement a lean manufacturing system at your workplace.

In this article, I am going to discuss the Toyota 3M model i.e. Muda, Mura, and Muri in detail, starting from fundamental concepts to the important strategies to reduce all three categories of Waste.

So that you can help your organization in achieving operational excellence. Are you ready to reduce the 3 important categories of waste in your organization? Let’s get started…

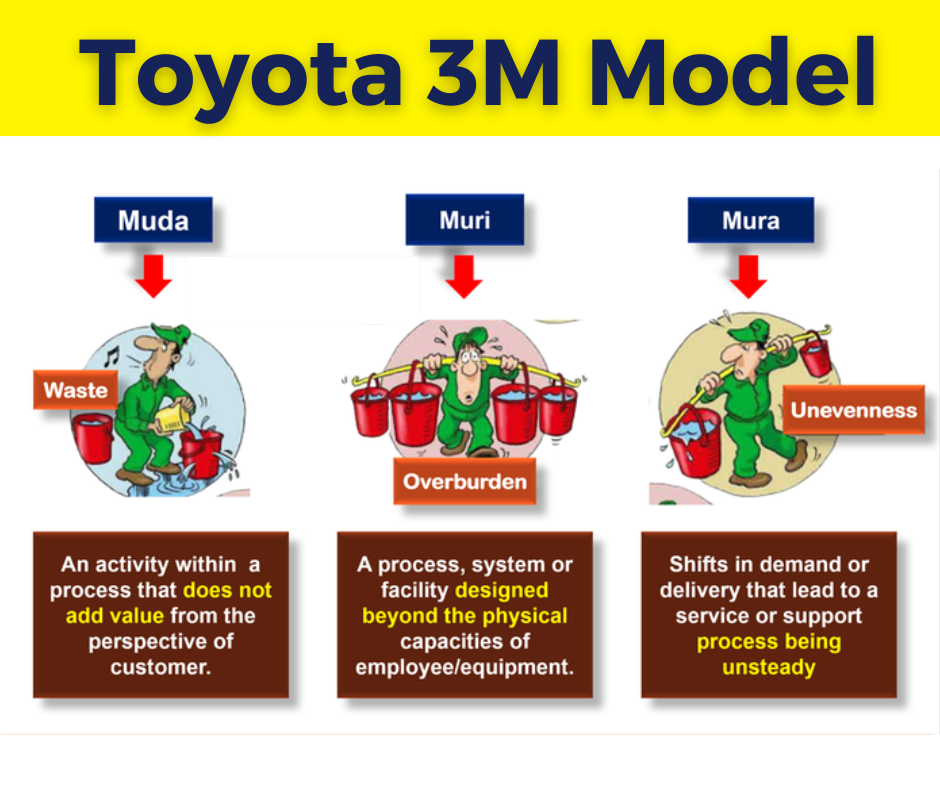

What is the Toyota 3M Model?

You know the powerful Toyota Production System developed by Toyota Corporation that changed the way industries operate completely. TPS also called the father of Lean manufacturing.

TPS is a powerful system that focuses on improving efficiency, eliminating waste, and continuously improving processes. All this is done with the help of Lean tools and practices like Just-in-time, Value Stream Mapping, Jidoka, Kaizen, and TPM.

It helped many organizations eliminate efficiencies and wastes within the processes. The goal of lean manufacturing is to eliminate waste or non-value-added activities from the process and make it more efficient from the customer’s point of view.

Initially, the lean manufacturing approach only focused on the elimination of waste (8 waste types) or Muda and the other two categories of waste like Mura and Muri were not in much focus.

Later it was observed that the root cause of Muda in the process is the presence of Mura and Muri in the process. That’s why it became important to address these 3M (Muda, Mura, Muri) together to improve process efficiency.

That’s how the Toyota 3M model (Muda, Mura, Muri) came into the picture, and focusing on this 3M waste became important for streamlining the process. Many organizations understood the importance of collectively reducing these 3 waste categories.

Later on 3M model Muda (waste), Mura (unevenness), Muri (overburden) became an integral part of the Toyota Production System which collectively described as non-value added activities from the process to be eliminated.

These 3M’s are enemies of lean implementation and can be found in any process like manufacturing or service. So the organization that implements lean practices now actively focuses on eliminating these 3M waste

To help your organization implement lean practices and streamline processes you need to understand these 3M (Muda, Mura, Muri) one by one and practical strategies to reduce each waste category.

Understanding the 3M Muda, Mura, Muri

Now you know the fundamentals of the Toyota 3M model. Let’s understand the 3 pillars of the Toyota 3M model (Muda, Mura, Muri) in detail along with practical strategies to reduce these 3 major wastes and help your organization in operational excellence.

Muda: (Waste)

Muda is a Japanese term that translates to Waste or futility, in simple words it is any activity, process, or resource that does not add value to the final product or service.

This is the 1st pillar of the 3M model (Muda, Mura, Muri).To understand this you need to first get clarity about the value-added and non-value-added activities.

Value-added activities or tasks in the process are those that actually transform your product from raw material to finished product or in service process context activity that you do from start to finish of the service to customers.

The most important is the customer is willing to pay for such activities becasue these activities add value to the final product or service and that’s why they are called value-added activities.

Examples of value-added activities are wielding, drilling, grinding, assembling components, painting the final product, etc. On the other hand, Non-value-added activities are those for which the customer is not willing to pay. See in this also there are two types of NVA.

The first category of NVAs are those that are necessary to perform to ensure a safe and quality product reaches the customer’s hand. For example Inspection, quality checks, testing, safety checks, etc.

The 2nd category of NVAs are all those that do not add any value to the final product excluding the first category of NVAs. These activities are pure waste that you need to eliminate or reduce in order to increase efficiency and streamline the processes.

This 2nd category of NVAs consumes resources, time, and effort without directly improving product quality. There are 8 categories of waste under this 2nd category of Non-value-added activities or Muda and it is popularly called DOWNTIME.

- Defects: Any errors or mistakes that lead to defects in the final product. When there are defects in the product then it can lead to rework, repair, scrap waste, customer complaints, and low quality.

- Overproduction: Producing more than the next step in the process needs or more than the customer buys. This waste can lead to waste of lot resources, time, and effort, excess inventory, and storage costs.

- Waiting: Non-productive time due to lack of material, people or equipment. It happens because of poor scheduling, bottlenecks, and non-balancing in the process.

- Non-utilized talent: Fail to fully utilize the skills, knowledge, and creativity of the employees. This can lead to a lack of engagement from employees at the workplace and decreased morale.

- Transportation: Unnecessary movements of materials and products between different locations or between different processes. This can lead to higher lead time and sometimes damage to materials or products.

- Inventory: Excess raw materials that are bought, invested in, and not immediately sold or used for production. This can lead to high overhead costs and chances of defective material being hidden in the finished goods.

- Motion: Unnecessary movement of people, equipment, or materials within the workplace. This can lead to burnout and a lot of wasted time.

- Overprocessing: It is nothing but the task, activities, and materials that don’t add value to the final product or service. This can lead to unnecessary inspection and additional processing steps.

These 8 categories of waste contribute to all 3M Muda, Mura, and Muri. So, to increase the efficiency and effectiveness of processes you need to focus on eliminating these 8 categories of waste in 2nd NVAs.

There are different waste reduction strategies you can use depending on your organization’s capability. Here let me share some strategies or powerful lean tools you can use to reduce or eliminate the Muda:

- By creating a value stream map you can identify the non-value-added and value-added activities. With this map, you can visually see the complete process flow. You can identify the areas of waste and bottlenecks, and then plan improvements accordingly.

- Use a Just-In-Time system to maintain the smooth flow of material and reduce waiting times. JIT focuses on producing only what is needed and when it is needed to minimize waste like overproduction and excess inventory.

- To control inventory level implement a pull-based system using kanban cards. This can ensure that the new raw materials are only ordered or produced when the existing ones are used.

- To reduce defects and motion waste you can implement a standardized work system. This tool helps in establishing standardized procedures and work methods to reduce the variation and errors in the process.

- Implement 5s methodology for workplace organization. This 5-step method helps you make your workplace clean, and clutter-free with proper SOPs, this ultimately improves your overall workplace efficiency.

- To reduce defect waste you can implement a poka-yoke system. The poka-yoke mechanism helps prevent errors or mistakes from happening in the first place. So there is no defect and no rework at the process output.

- To reduce Motion waste you can use SMED. This minimizes downtime and increases flexibility by reducing changeover time and enabling quick transitions between different production processes or tasks.

- Implement a visual management system using things like color coding, labels, and charts to make information easily available to everyone at the workplace and this improves communication across teams and ultimately helps in waste reduction.

- A permanent way to reduce Muda is by promoting a culture of continuous improvement at your workplace, where all the employees come together to suggest new ideas for improvement and actively engage in waste reduction activities.

Mura: (Unevenness)

The 2nd pillar of the 3M model (Muda, Mura, Muri) is Mura, which is also called unevenness, inconsistency, or irregularity in the process. In simple words, it is the variation, inconsistency, or deviation that occurs in the process that leads to defects or inefficiencies.

See, when there are inconsistencies in the process you can find the fluctuation in the production process. When there is fluctuation or variation in the production process, employees need to overwork when demand is high, and when the demand is low, employees sit idle.

Due to such unevenness in the process, when employees are overworked there is a high chance of defects coming at the output of the process. On the other side, when employees sit idle becasue of low demand this leads to waiting and inventory waste,

In both cases because of unevenness in the process, there is a possibility of generating wastes like overproduction, waiting, defects, and inventory, That means Mura ultimately leads to Muda.

Let’s see some examples of different types of Mura from the 3M model (Muda, Mura, Muri):

- You see variations in the type of products being produced in the organization. Such frequent changes in the product specifications or final design can lead to longer set-up times and also increase the chances of errors or mistakes in the product.

- You also see inconsistencies in the timing of production processes. If different production stages are not well synchronized, then it can lead to idle time, bottlenecks, and improper utilization of resources in the process.

- You also see the variations in the performance of equipment or machines used in the production process. Such machine or equipment breakdown or their uneven performance can lead to delays, and defects and affect overall efficiency negatively.

- Then the most common you see is variation or fluctuations in the production demand. If the production level continuously varies then it can lead to both overproduction as well as underproduction. Both are in the end waste in the process.

So, in order to achieve a smooth and consistent process flow you need to focus on reducing the Mura (unevenness). When unevenness gets reduced in the process, you can see a reduction in the waste as well as an improvement in the product quality.

There are different Mura reduction strategies you can use depending on your organization’s capability and those are pretty similar to Muda. Here let me share some useful strategies you can use to reduce or eliminate the Mura.

- Establish standardized work processes that outline the best practices for performing process-related tasks. This standardization helps reduce the variations in how the process-related tasks are carried out and eliminates inconsistencies.

- Instead of a Push system, use a pull-based system using a Kanban card. This helps in reducing unevenness as the work is only initiated when there is demand from the customer side.

- Use process maps like Value Stream Map to visualize the flow of material and information in the process. With the help of VSM identify potential areas of Mura and then take necessary action to reduce it.

- Implement the Hiejunka Production leveling approach, which focuses on producing a consistent quantity of products over a specific time period. This helps in managing the fluctuation in production demands.

- Use visual clues at the workplace like color coding, labels, boards, and indicators to make inconsistencies in the process immediately noticeable. This helps people who are working close to the process, identify and correct issues fastly.

- Use the Kaizen philosophy at the workplace, where you can encourage employees to identify and address the small inconsistencies or variations in the process regularly. This helps reduce Mura over a period of time.

- Apply the concept of Takt time practically by distributing tasks and workloads equally among the workers or machines to prevent bottlenecks in the process and overburdening. This helps in maintaining a steady process flow without unevenness.

Muri: (Overburden)

Muri the 3rd pillar of the 3M model (Muda, Mura, Muri), which simply means overburden. This refers to overburdening or overstraining people, equipment, and systems beyond their capabilities.

This happens becasue of variation or unevenness (Mura) in the process. Due to variations or fluctuations in demand employees and machines put extra effort into completing the work and this puts too much stress and strain on people, machines, and complete systems.

You see sometimes there is a huge monthly target in front of the organization, and to meet that target employees work hard with extra effort and machines also operate to their complete capacity.

This practice of pushing resources beyond their capability or limits results in defects, inefficiencies, downtime issues, inventory flow problems, and waiting waste in the process.

It starts with Mura, When there is Mura (unevenness) in the process then there is a high chance of Muri (overburdening issue), and both these lead to Muda (Waste) in the process. Then all three wastes negatively affect the process efficiency.

Let’s see some examples of different types of Muri from the 3M model (Muda, Mura, Muri):

- Assigning tasks to workers, that are too physically demanding and expecting them to work beyond their physical limits.

- Running machines or equipment beyond their designed capacity.

- Unevenly distributing the workload amongst the workers and similarly uneven distribution of workload on different machines at the workplace.

- Poorly designed processes with unnecessary movement of workers, waiting time in between process steps, and too much material handling in the process.

- Setting unattainable targets without considering the available resources, equipment, and time (for both manufacturing or service processes).

There are different Muri reduction strategies you can use depending on your organization’s capability and those are pretty similar to Muda and Mura. Here let me share some useful strategies you can use to reduce or eliminate the Muri.

- The most important thing is to distribute workloads equally among all the workers or employees to prevent individuals from being overburdened with a lot of work.

- While assigning the task at the workplace balance workload by considering the skillset and capacity of each individual.

- Perform capacity analysis by evaluating the capacity and capability of all resources at the workplace like machines, equipment, and people.

- Focus on avoiding pushing these resources beyond their capacity otherwise, it leads to machine downtime and burnout of people.

- Implement 5s methodology for workplace organization. This tool helps reduce unnecessary movement and waste of time and energy at the workplace by properly optimizing the workplace with the 5 powerful steps Sort, Set in order, Shine, Standardize, and Sustain.

- Use the Value Stream Map to identify the value-added and non-value-added activities in the process. Get a complete visual picture of the process with the help of VSM.

- To streamline the process focus on value-added activities that contribute to output and eliminate all non-value-added activities, this will automatically reduce the overburden issue.

- Implement standardized work procedures and processes to eliminate variations and unevenness in the process, which will automatically reduce the Muri (overburden).

- Standardized processes ensure that all process-related tasks are completed consistently and efficiently. That means standard Work simply reduces the overburden issue.

- While setting targets, whether it is production process targets or service process targets make sure that targets should be based on available resources, capacity, and actual demand. This helps reduce the overburden or overutilization of all the resources.

Conclusion

The Toyota 3M model (Muda, Mura, Muri) focuses on identifying and eliminating wasteful practices, reducing variation and inconsistencies in the processes, and preventing the overburdening of people/machines.

By embracing the 3M model (Muda, Mura, Muri) organizations not only enhance their operational excellence but also foster a culture of continuous improvement by empowering everyone in the organization to be a catalyst of change.

In this article, I discussed the 3M model (Muda, Mura, Muri) in detail with examples and practical strategies to reduce all 3 waste categories. Start working on reducing these 3 wastes and help your organization propel towards efficiency, quality, and excellence.

If you found this article useful then please share it in your network and subscribe to get more such articles every week.

Well done , Explained.

Some Thoughts:

As you review the Value ( invest of all resources) of each added action

How does it compare to pre defined value.

Going forward-robustness of value chain depends on robustness of each of the individual LINK.

For lasting robustness of system it is imperative to builtin verification of value achieved