Problem-solving is now becoming essential for companies to stay ahead of the competition. 8D problem solving is one of the most popular methodology used in all industries for solving technical problems at the workplace.

This methodology uses many of the tools from six sigma but focused on identifying, correcting, and preventing a problem. This methodology is not part of six sigma but they do help in many situations to structure the problem-solving process and find its solution.

In this article, we will understand the 8D problem solving methodology in detail along with a case study example so that at the end you will become ready to implement it. Let’s start…

What is 8D problem solving methodology –

Before getting into this let’s understand the simple question, what is meant by a problem?… A problem is a situation you want to change or it is an opportunity for improvement, right!

In the context of Six Sigma, the problem is nothing but the out-of-control situation, waste in the process or special causes of variation, etc.

Generally, there are two causes of variation which are responsible to disturb any process i.e. Special cause of variation and a common cause of variation. The focus of any problem-solving tool is to reduce these variations as much as possible.

Suppose, If we plot the control chart, in that any data point that is beyond the upper and lower limits indicates that the process has special causes of variation, and when all the data points are within these limits that means our process has only a common cause of variation.

Common causes of variation are an integral part of any process, they cannot be eliminated completely from the process.

We can reduce it up to a certain level so that the process performs effectively and efficiently. Six Sigma methodology is useful to reduce these common causes of variation by using the DMAIC process.

But when there is a special cause of variation in the process, it is an indication of disturbances in the process which then increase the variability of the process beyond acceptable levels.

These causes of variation must be eliminated from the process to make it stable. Here comes the use of 8D problem solving methodology. This 8D methodology is useful to eliminate all the special causes of variation to bring long-term stability to the process.

Six Sigma – Useful in reducing common cause of variation.

8D problem solving – useful in eliminating special cause of variation.

This problem-solving methodology is designed to define the problem in the process and find the root cause of that problem. It focuses on implementing a long-term solution to prevent the reoccurrence of the problem.

History of 8D methodology –

8D has its origins in the united states military and also in the automobile industry but nowadays it is extensively used in all industries like food processing, healthcare, tech manufacturing, services, etc.

In 1980, Ford Motor Company developed team-oriented problem solving which then become an 8D problem solving methodology.

Due to its effectiveness, it was accepted as a primary method of problem-solving at Ford. After it becomes popular at Ford and because of its effective results, 8D methodology was globally accepted as the best problem-solving method to tackle engineering problems.

The name 8D stands for the disciplines covered in this methodology or the 8 steps of problem-solving. These steps are identified as D0 to D8 and it follows the PDCA cycle (Plan – Do – Check – Act).

The goal of this method is to find the root cause of a problem, develop containment action to protect customers, and take corrective action to prevent similar problems in the future.

What are the 8 disciplines of 8D problem solving –

8D methodology is the combination of 8 steps or disciplines starting from D1 to D8 in which professionals work together to solve problems and create effective solutions for that problems.

Initially, it is comprised of 8 stages of problem-solving later it is updated with the initial planning stage D0 so now 8D becomes D0 to D8 steps.

This is a very structured and highly disciplined methodology of problem-solving which drives systematic changes or improvement in the process by preventing problems.

We will discuss how this 8D problem solving works later in this article but for now, Let me list down all the steps of this powerful method.

When to use 8D problem solving –

This powerful problem-solving methodology is required when…

- There is a need to find a permanent solution to the problem and prevent the recurrence of that problem.

- There is a need to develop containment action to protect customers, and take corrective action to prevent similar problems in the future.

- Customer complaints are received (when they are unhappy with product/service performance.)

- There is more amount of internal rejection, waste, and scrap in the process which makes process performance poor.

- There is a failure in a system or in a process beyond the acceptable levels.

- There is safety or regulatory issues that occurred.

How to apply eight disciplines of (8D) problem-solving –

Now let’s get into the depth of each discipline and understand what will happen in each discipline and as problem solvers what you need to do –

D0 – Prepare and plan for 8D –

Proper planning is important to implement 8D problem solving successfully. This stage is all about finding the problems and prioritizing them.

You may find multiple problems and all seem to be urgent hence main task here is to identify the main problem on the basis of its impact or importance and the urgency to resolve it.

We need to properly understand the customer complaint data and then check which complaint needs an emergency response to protect the customer from further consequences.

At this stage, we can use tools like Pareto analysis to select and prioritize the problem. This tool gives us a clear picture of the problem and tells us where we need to do the investigation.

At the time of the planning stage, we need to consider –

- Who will be on your team?

- What is your time frame?

- What resources will you require?

- Is it a new problem or already occurred?

- What is the history of the problem?

- If it occurred before then how it was solved at that time?

D1-Grab a team

To implement this team-oriented problem-solving methodology we need a cross-functional team of quality professionals, process owners, subject matter experts, team leaders, and sponsors. This stage is all about forming a team of people with product or process knowledge.

The team leader should be the person who has the right expertise to solve problems and knows how to implement the 8D process or the person who works close to the process i.e. process owner. Then there is an 8D moderator or SME, the person who is trained in 8D and guides the team by giving them feedback.

On the other hand, the Sponsor is responsible for resources and they support the team in any financial decision-making and give the authority to implement corrective action.

And at last, there are team members who are experts assigned to work on the problem with their specific knowledge. Time and resources are allocated to them so that they can work on the problem as per the 8D problem solving process.

List of team members who are generally part of this project –

- Process owner

- SME’s

- Quality engineers

- production staff

- Sponsor

- Team leader

D2-Understand the problem

A properly defined problem is a half-solved problem. At this stage, describe the problems in such a way that it is easily understood and can highlight the issue faced. While highlighting the problem you need to focus on Where, When, and How.

For Where type questions ask like where did the problem occur? which site of the company? which location in the company or which process line has a problem etc. Is the problem with a single process/product or does the entire batch have a problem? etc.

For when type questions ask like when was the first occurrence of the problem? Is there any time pattern? Does it occur after every cycle, every day, or every shift? Focus on when exactly the problem occurs.

For how type question ask like how many products affected? how many processes have these problems? All the answers to such questions must be based on facts and exact data. This helps to understand the exact problem.

Understanding the problem becomes easy when we focus on these types of questions. We can use tools like cause & effect diagrams, 5 why analysis, or affinity diagrams to get more information about the problems.

D3-Take containment action

At this stage, we need to define and implement the containment action that will protect the customer from the problem.

It is the temporary action implemented till permanent corrective action is implemented and validated. This action will be discontinued after the positive results of the validation of permanent corrective action.

It is the quick fix of a problem for example- Shutdown of the machines that are not working. So that we can stop the production of defective parts. That means the target of this action is to protect customers from future consequences.

During this stage, we need to maintain communication with the customer because of containment action there may be a delay in the delivery of the product so discussion with them helps to maintain trust.

Examples of Containment action-

- Stoppage of production.

- Informing the customer about the problem.

- Informing operators about the problem.

- Additional visual control.

D4- Find the Root cause

Identification of the root cause is very important. If it is properly identified, it can be acted upon and recurrence can be prevented from that root cause.

The location of that root cause also needs to be identified. More than one root causes are responsible for the problem.

To identify this we can use tools like root cause analysis, fishbone diagram, 5 why analysis, and Is/Is Not analysis. Well, you are familiar with other tools but Is/Is Not analysis is something new. Let me give you one example to show what this tool is…

For example – If there is a problem and you start assessing the situation with questions starting from Where When etc. we already discussed this.

In this analysis, we look for both sides of the question. Where is the problem and where is not the problem or we can ask when the problem occurs and when it does not occur? This type of questioning helps us to set some boundaries for the problem study.

For example – The problem is in product A and it is not in products B and C these answers we will get and after that, we can only focus on product A for further problem study. That’s how Is/Is not analysis works.

List of tools used for finding root cause-

- Pareto charts

- Affinity diagram

- Brainstorming session

- 5-why analysis

- Fishbone diagram

- Fault tree analysis

- Flow chart

- Statistical analysis

- Hypothesis testing

- Regression analysis

D5- Choose permanent corrective action

Permanent corrective action is the action that removes product/process/system condition which is responsible for the generation of the problems. The determination of this permanent action is dependent on the root cause identified in the D4 stage.

Basically, at this stage, we want to remove the root cause of the problem by choosing effective permanent action.

There can be more than one permanent action so to choose the best from it we can brainstorm with team members also we can use the affinity diagram tool.

During brainstorming, team members look for acceptance criteria to select the permanent action, they evaluate the risk associated with the particular permanent action and make a balanced choice. Hence the goal of this stage is to remove the cause & effect link completely.

Criteria for choosing the best corrective action or solution for the problem –

- Practical – 8D team should be able to implement the solution practically.

- Feasible – The solution must be feasible.

- Cost-effective – Implementing and using the solution must be cost-effective.

- Robust – The solution must be robust so that it should not fail when it is implemented practically.

Examples of permanent corrective action –

- Introducing additional control in the process.

- Rework defective units found in the process.

- Rework units returned from the customers.

- Inform the supplier about defective parts delivered and their exchange.

- Implement visual control at the workplace.

- Implement Poka-Yoke

D6- Implement and validate corrective action

Once the permanent corrective action is determined it is implemented and for effective implementation, we need to focus on proper planning. We need to create an action plan that includes information like what steps are needed to implement the solution, who will do them, and when they will be completed.

Communicate the action plan and all the changes with team members as well as with people who are working in that area and make sure everyone in the team follows the action plan and tracks results.

At this stage, we also need to prove the effectiveness of the permanent action. After its implementation, we have to recollect the response data about that process.

Service or sites to understand how this permanent solution works. That means we have to verify the effectiveness of the solution.

Then accordingly team updates all the documentation plans, work instructions, and failure effect analysis data once the validation of corrective action is done. That’s how this stage completely focuses on the implementation and validation of the solution.

List of tools used during this stage –

- Check sheets

- Run charts

- Control charts

D7- Learn and define prevention for the future

This stage is more like the control phase of the DMAIC project where we need to control the improvements made on the process and ensure that gains obtained during the project are maintained long after the end of the project.

Similarly, at this stage of 8D problem solving, the team focuses on the active prevention of the reoccurrence of the problem. They review similar services/products or processes in the company to prevent a recurrence.

The team actively presents the 8D methods to experts at other process lines or at other sites of the company so that they can actively work on the prevention of problems.

Process owners and upper management work together to share the learnings of 8D across the company and execute 8D training at different processes or product lines. These learning documents consist of updated procedures and work instructions for the prevention of problems.

Also, the team develops a new set of standard operating procedures that everybody needs to follow who works in that area or at the process line, etc. in order to prevent the recurrence of the problem.

They proactively update the failure mode effect analysis document and control plans because these two tools help us identify the problem area and then prevent its occurrence.

List of tools used during this stage –

- FMEA

- Control plans

- Control charts

- Histogram

- Capability analysis

D8- Congratulate and release the team

This stage is one of the most important disciplines of 8D problem solving, here the team leader should recognize the team and individual efforts, recognize those who perform best during the project, and then congratulate all the team members as well as the main contributors to this project.

Recognition is important because we don’t know when we need these team members again so if the team leader appreciates their effort at the end of the project then team members feel motivated and they will be always ready to work with the leader in the future.

After this team leader declares the formal closure of the 8D project by documenting all the lessons learned. Finally, all the documentation is completed in the form of an 8D report which is available for all the employees at the company for learning purposes.

This stage is all about the documenting final 8D report and celebrating the successful completion of the 8D project.

That’s how the 8 disciplines of 8D problem solving methodology work. The most important part of this method is the 8D report which consists of a quick summary of the entire problem-solving project. Now let’s see what the 8D report means…

What is 8D report?

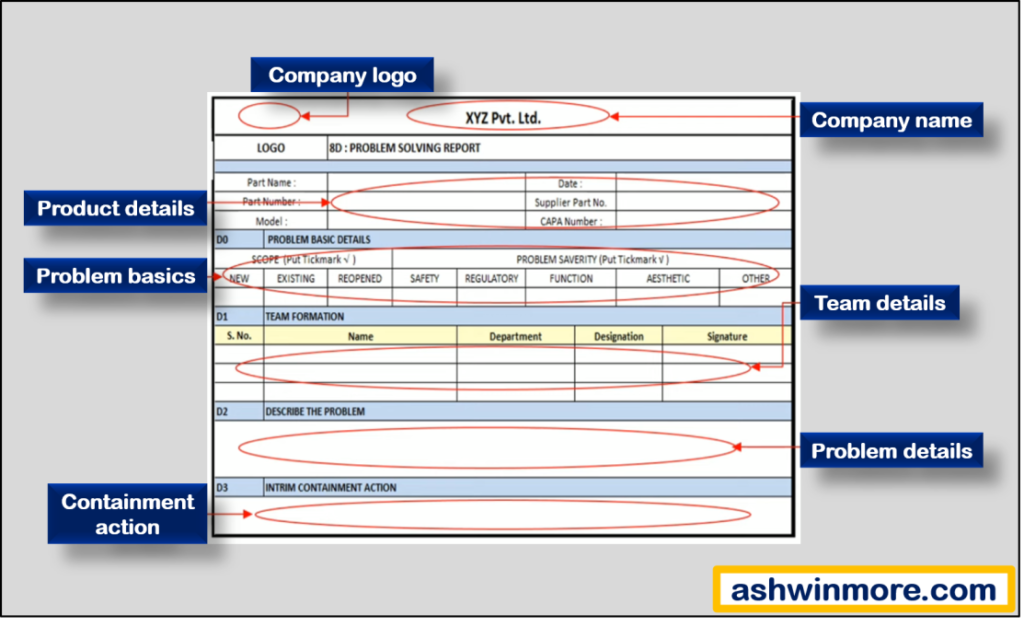

The output of an 8D project is the 8D report and this is first used in the automotive industry. Here we will go through a basic example of the 8D format in order to understand what it includes and its structure. 8D report has 3 parts let’s see them one by one…

In the first part (as per sample 8D report picture), we have to fill in our company information like name and logo. Then, we have to fill in information about the parts/process where we performed this project and the date(when the problem occurred).

After that in the next section, we have to fill in information about the problem basic like whether the problem occurred for the first time or it is repeated and how much severity it has.

Then in the next section, we have to add the team member information like their names and sign. After that in the next section, we have to add detailed information about the problem.

Then there is a section of containment action, in which we have to add what type of containment action we have taken to avoid more damage. Provide details about containment action.

In the second part (as per the sample 8D report picture), initially, we have to add our cause & effect diagram with a detailed analysis that includes all the possible causes classified into different categories.

After that, there is a section on the Root cause, see during cause & effect analysis we found the possible causes and then we segregated potential causes from that. By using tools like 5 why analysis, we found the root causes of all these potential causes, that root cause information we have to add in this section.

Then in the next section, we have to add information about the corrective action which we have taken to prevent the occurrence of the problem.

Next to that section, we have to add validation results of corrective action, after testing the correction action and how it works, that information we have to include here.

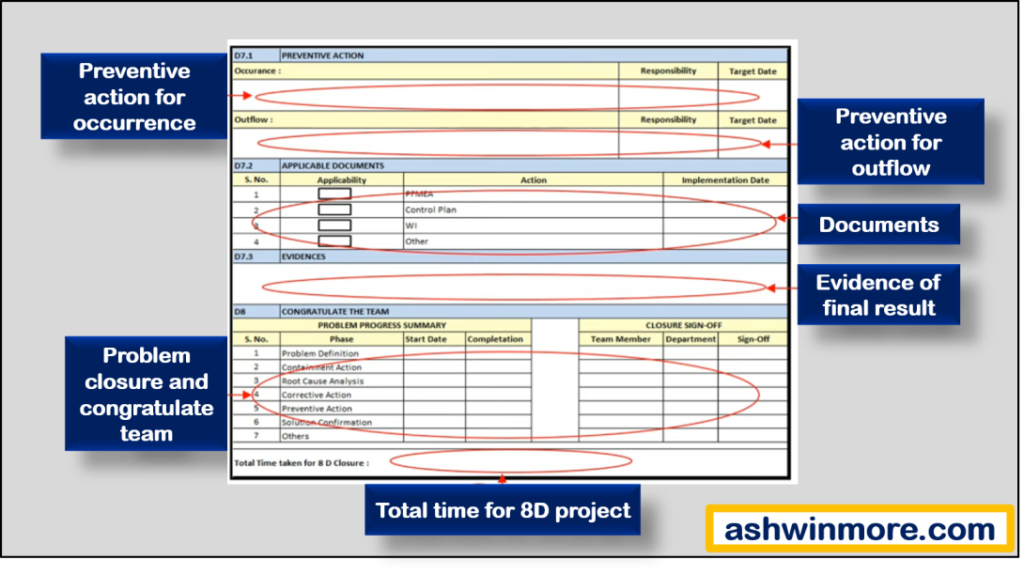

In the third part (as per the sample 8D report picture), We have to add a list of the preventive action taken. Next to it, we have to add information about all the documents created during the project like a list of documents and the name of updated documents.

After that, we have to add evidence of the final results like photographs, graphs, control plans, etc. At last, there is a section on problem closure and sign-off, which includes a summary of all 8 disciplines or 8D steps like the start and end date of each step.

Then there is sign-off from all the team members which shows this project successfully completed. At the bottom mention the total time required to complete the 8D project.

This is the basic structure of the 8D report, it is different for different companies so there is no standard for it you can select as per your company. I hope you got the basic idea of the 8D format. (Check out 8D report template)

Benefits of 8D problem solving method-

8D is the structured and highly disciplined methodology of problem-solving. Proper implementation of this methodology can provide the best results. It is easy to learn and applicable to solving any type of engineering problem. Here is the list of benefits of 8D problem solving –

- This methodology builds a culture of team-oriented problem-solving instead of individual problem-solving. Inspire the employee to work together in a team to solve any engineering problem.

- It improves the awareness amongst the employees as well as management about understanding the problems and ways to find solutions.

- It increases customer satisfaction, profitability, and market share of a company.

- It increases the practical understanding of Root cause analysis.

- It increases the understanding of statistical tools amongst the employee that are used in problem-solving.

- It improves the skill of implementing permanent corrective action and validates its results.

- This methodology helps to create a proper action plan to prevent the reoccurrence of problems in the future and engage everybody in this process.

- This methodology helps in bringing about systematic change rather than just quick fixes.

8D problem solving case study –

Until now we discussed everything about 8D problem solving so it’s time to understand how it works practically. With this case study, we will understand How the 8 disciplines of the 8D methodology work. Lets’ see –

Practical implementation of 8D at car washing center. (Scenario)

“TATA motors have a car wash service center in Bombay city (Bombay – a popular city in India). TATA motors recently ran into problems with some of their customers which causes damage to their reputation.

Also, they have built over a long period, incurring financial damages from litigation from angry customers and losing their loyal customer base to their competitors.

Recently, the shift operator discovered that some of the cars coming out from one of three car wash machines have scratches on the rear body. The problem was fixed by calling a technician.

But again after two weeks, the problem started re-occurring, and this time the scratches were even more worst. This was discovered by the evening shift operator who notified the supervisor.

TATA motor’s head office sends the quality control supervisor to the car wash center to deal with this problem. After analyzing the situation he came to the conclusion that to properly solve this problem we have to use the 8D problem solving approach.

To prevent further damage to the machine, the quality supervisor immediately instructed the operator to shut down the faulty car washing machines. Customers were already waiting to resolve this problem.

The quality supervisor invited the engineer, operator, car wash center supervisor, and service technician to a brainstorming session. Everybody on the team knows that due to this problem our company facing negative feedback from customers.

During the brainstorming session, they discussed the questions like who discovered the scratches? What did those scratches look like? when it was first noticed? after how much time it re-occurred? etc. Everybody on the team puts their own opinion during the discussion.

At the end of a brainstorming session, they gather the data and the team comes to the conclusion that the problem is due to the malfunctioning of a particular sensor in the machine.

The engineering team looked into this and found that the machine had a sensor calibration problem in which the sensor periodically malfunctioned.

They found the problem and now the team wants to know the reason behind that problem so that they can find a permanent solution for that.

After performing a Root cause analysis they found that this problem happened due to the annual servicing of the machine being 4 months late.

To fix this problem, the 8D problem solving team instructed the car washing center supervisor to call a specialist to do servicing of problematic machines and repair or replace that non-functioning sensor.

After fixing this, the team collected the data of that machine (which had a sensor problem earlier) in order to validate whether that machine working properly or not.

After 9 hrs the machine was continuously tested and as a result, it was found that there were no scratches, and cars were washed from the center there were no new reports regarding the scratches.

In order to address the angry customers, the 8D team suggested a car wash center to give them some concession for car washing and respond to all their feedback.

Then 8D team created an action plan or strict guidelines for the servicing procedure of all the 3 car washing machines to prevent the recurrence of the problem. All the important lessons learned during this project have been documented for future reference.

In the end, the quality supervisor who is the team leader of this 8D project appreciated all the teammate’s efforts and congratulated them on the successful completion of the project.”

This is a complete problem scenario we discussed and now below we documented all these scenarios in the form of 8 disciplines of problem-solving.

OD – Aware of the problem

A Shift operator discovered that a number of cars coming out from one of the three-car washing machines have scratches on the car body.

1D -Grab the team

The quality supervisor invited the engineer, operator, car wash center supervisor, and service technician to a brainstorming session in order to discuss the problem.

2D- Understand the problem

At the end of a brainstorming session, they gather the data and the team comes to the conclusion that the problem is due to the malfunctioning of a particular sensor in the machine.

In order to come to this conclusion, they studied questions like who discovered the scratches? What did those scratches look like? when it was first noticed? after how much time it re-occurred? etc.

3D -Take containment action

To prevent further damage to the machine, the quality supervisor immediately instructed the operator to shut down the faulty car washing machines.

4D – Find the root cause

The engineering team looked into this and found that the machine had a sensor calibration problem in which the sensor periodically malfunctioned.

They found the problem and now the team wants to know the reason behind that problem so that they can find a permanent solution for that.

After performing a Root cause analysis they found that this problem happened due to the annual servicing of the machine being 4 months late.

5D – Choose corrective action

To fix this problem, the 8D problem solving team instructed the car washing center supervisor to call a specialist to do servicing of the problematic machine and repair or replace that non-functioning sensor.

6D – Implement Corrective action

The team collected the data of that machine (which had a sensor problem earlier) in order to validate whether that machine working properly or not.

After 9 hrs the machine was continuously tested and as a result, it was found that there were no scratches, and cars were washed from the center there were no new reports regarding the scratches.

7D – Prevention for the future

8D team created an action plan or strict guidelines for the servicing procedure of all the 3 car washing machines to prevent the recurrence of the problem. All the important lessons learned during this project have been documented for future reference.

8D – Release the team

The quality supervisor who is the team leader of this 8D project appreciated all the teammate’s efforts and congratulated them on the successful completion of the project.

That’s how this problem in the car washing center was permanently solved using 8D problem-solving and in the end, the team created an 8D report for further learning. This example shows how effectively we can apply this methodology to solve technical problems.

Conclusion –

Well, I hope you got the basic idea about the powerful tool called 8D problem solving. We discussed all the concepts related to this methodology and also discussed the eight disciplines of this method along with what happens during each discipline and which tools we need to use.

We also understood when to use this tool and what are its benefits. We also discussed the concept of the 8D report, and what it looks like. In the end, we covered one basic case study to understand how 8D problem solving works to solve real-life problems.

If you found this article useful then please share it in your network and subscribe to this platform to get more such articles every week. We will meet again in the next article!

Frequently asked question

What is 8D problem solving process?

This problem-solving methodology designed to define the problem in the process and finding the root cause of that problem. It focuses on implementing a long-term solution to prevent the reoccurrence of the problem.

What does 8D stand for?

The name 8D stands for the disciplines covered in this methodology or the 8 steps of problem-solving. These steps are identified as a D0 to D8 and it follows the PDCA cycle (Plan - Do - Check - Act).

Is 8D a Six Sigma tool?

8D methodology uses many of the tools from six sigma but focused on identifying, correcting, and preventing a problem. This methodology is not part of six sigma but they do help in many situations to structure the problem-solving process and find its solution.

Thankyou for sharing the information. Website is so easy to use – I am impressed with it.

thanks a lot, it is a very professional methodology

Your welcome

Thanks for your feedback!

Pingback: Explain Total Quality Management and Its 8 Key Principles

GOOD EXPLANATION IN DETAIL

it’s very good explanation..

Thanks for your feedback!

Best explanation for forever to apply knowledge

Thanks for your feedback!

Appreciate you sharing, great article post. Really looking forward to read more. Cool.

Thanks for your feedback

Pingback: How Root Cause Analysis can help you solve complex problems?